Whether used in car engines or industrial equipment, an excellent antifreeze requires not only superior thermal conductivity and freeze protection but also an ideal viscosity to ensure its effective retention and coverage within complex systems. The key to achieving this goal often lies in its core additive – Hydroxyéthylcellulose (HEC).

Ⅰ. What is Hydroxyethyl Cellulose (HEC)?

To understand why HEC is so effective, one must first understand the Hydroxyethyl Cellulose Structure. HEC is a non-ionic synthetic polymer, produced by the hydroxyethyl etherification of natural cellulose. This unique chemical structure gives it excellent water solubility and thickening ability, while maintaining the eco-friendly characteristics of natural products.

Its core physical properties, such as Hydroxyethyl Cellulose Viscosity, can be precisely controlled through production processes, enabling the manufacture of products suitable for different viscosity grade requirements. Furthermore, Hydroxyethyl Cellulose Solubility is exceptional; it dissolves rapidly in both cold and hot water, forming a clear, transparent viscous solution that does not affect the color or transparency of the antifreeze itself.

Ⅱ.Why Choose HEC as a Specialized Thickener for Antifreeze?

Among numerous thickener options, HEC stands out as the preferred choice for high-end Antifreeze Coolant formulations due to its comprehensive advantages:

Precise Viscosity Control: Professional Hydroxyethyl Cellulose Manufacturers can provide products with different viscosity grades, allowing formulation engineers to precisely adjust the antifreeze’s viscosity, ensuring perfect film formation on vertical or inclined surfaces without running or dripping.

Excellent Shear Stability: HEC solutions exhibit good rheology; viscosity temporarily decreases during spray application (under high shear conditions), facilitating easy application. Upon application, the viscosity immediately recovers to a high state, firmly adhering to metal surfaces.

Broad Compatibility: As a non-ionic polymer, HEC has excellent compatibility with antifreeze agents like ethylene glycol, propylene glycol, and various rust inhibitors and corrosion inhibitors. It does not cause salting-out or flocculation, ensuring the long-term stability of the Antifreeze Coolant Formula.

Thermal Stability & Environmental Friendliness: HEC performs stably over a wide temperature range and is biodegradable, meeting the high modern standards for environmental protection and safety.

Ⅲ.How to Successfully Apply HEC in Antifreeze Formulas?

Industrial Anti-icing Fluid Formulation

Component | Fonction | Recommended Dosage (wt%) | Key Remarks |

Ethylene Glycol / Propylene Glycol | Base Antifreeze Agent, Lowers Freezing Point | 40% – 60% | Dosage determines freezing point (-30°C to -50°C). Propylene glycol is more environmentally friendly. |

Hydroxyéthylcellulose (HEC) | Core Thickener, Provides Adhesion | 0.4% – 0.7% | Recommended Viscosity: 100,000 mPa·s. Ensures wall adherence and prevents runoff. |

Sodium Molybdate | Corrosion Inhibitor, Protects Steel | 0.8% – 1.2% | Environmentally friendly anodic corrosion inhibitor. Synergistic effect with borax. |

Borax | Buffer & Corrosion Inhibitor, Stabilizes pH | 0.8% – 1.2% | Maintains system pH between 8.5 – 9.5. Enhances anti-corrosion effect. |

Benzotriazole | Copper Corrosion Inhibitor, Protects Copper Components | 0.1% – 0.2% | Specific copper protection. Prevents electrochemical corrosion. |

Deionized Water | Solvent, Makes up Balance | Balance | Must be used to prevent impurity ions from compromising stability. |

A successful Antifreeze Coolant Formula relies on the correct use of HEC. Its Solubility is key to the application:

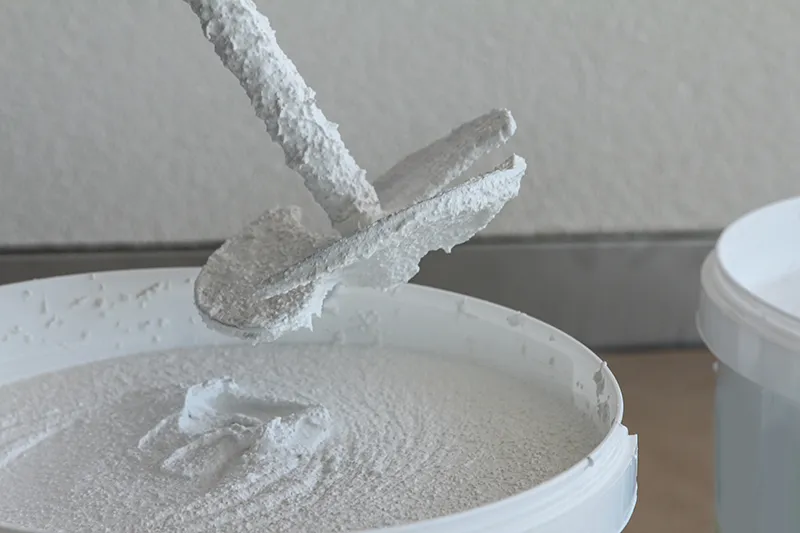

Dispersion : Under high-speed agitation, slowly add HEC powder to water, ensuring thorough dispersion and avoiding the formation of hard-to-dissolve lumps.

Dissolution & Activation: After uniform dispersion, adjust the system pH to the alkaline range of 8-9. This significantly accelerates its hydration and dissolution, rapidly forming a homogeneous, transparent viscous solution.

Blending: Finally, mix the fully dissolved HEC gel solution with the core antifreeze agents, corrosion inhibitors, and other components to obtain the high-performance final product.

Ⅴ.Conclusion

In summary, with its unique molecular structure, excellent solubility, and precisely controllable viscosity, Hydroxyethyl Cellulose has become an indispensable thickener for enhancing Antifreeze Coolant performance. Whether the goal is to improve product cling, reduce waste, or enhance the overall stability of the formulation, HEC provides an ideal solution. TENSITE, as a reliable Hydroxyethyl Cellulose supplier, will leverage its expertise in chemical manufacturing and strict quality control to provide you with high-performance HEC products and comprehensive technical support.