Ⅰ.Product Introduction

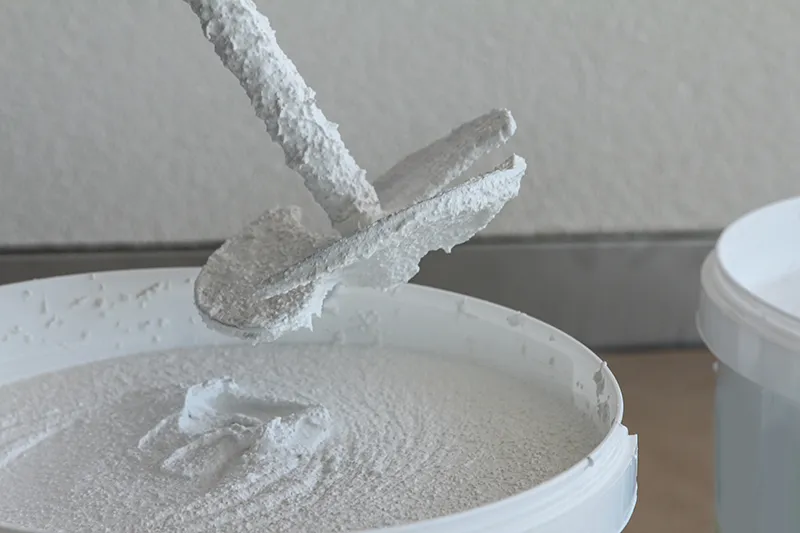

Flake Polycarboxylate Superplasticizer (PCE) ,This is a new generation of environmentally friendly, high-performance polycarboxylate superplasticizer flakes developed by our company. It uses modified polycarboxylate ether as the primary raw material.

Ⅱ.Performance characteristics of flake PCE

- High water-reducing rate: It has excellent dispersibility and the water-reducing rate can reach more than 25% at saturated dosage. Some products, such as FLT40 polycarboxylic acid-based high-performance water-reducing agent, can even achieve a water-reducing rate of more than 34%, which can effectively improve the working performance of concrete, increase concrete strength, and save cement.

- Good slump-preserving performance: It has good water-reducing and slump-preserving capabilities, can enhance the cohesion of concrete, prevent concrete segregation, extend the transportation time of concrete and the retention time on the construction site, and ensure the pumpable construction performance of concrete.

- Strong adaptability: It has excellent adaptability to different cements, whether it is various Portland cements, ordinary Portland cement, slag Portland cement and various admixtures, it can exert good dispersibility and water-reducing performance.

4.The strengthening effect is significant: itrowth rate of concrete, while improving the shrinkage performance, reducing the carbonization rate of concrete, and helping to improve the overall quality of concrete.

Ⅲ. Application Area

- Ready-mixed concrete: Suitable for various ready-mixed concrete, especially special dry-mixed mortar, which can be used for cement-based self-leveling, non-shrinkage grouting materials, grouting agents,self-leveling floors, su geçirmez harç,tamir harcı, sprayed mortar, dry-mixed high-strength concrete, etc.

- Special mortar: specially used for gypsum-based and cement-based special dry-mix mortar, which can meet their requirements for fluidity, water retention and strength.

Ⅳ.Detailed parameters

Ⅴ.How to use flake PCE

项目Project | 单位Unit | 标准Standard |

Görünüş | / | White or light yellow flakes |

Yığın Yoğunluğu | Kg/m³ | 500± 100 |

pH Value (23°C) | / | 6.0± 1.0 |

Available Content | % | 97.0± 1.0 |

Water Content | % | ≤ 3.0 |

Water Reduction Rate | % | ≥ 25 |

Chloride Ion Content | % | ≤ 0.02 |

Alkali Content | % | ≤ 0.3 |

The use of flake PCE must follow the principles of “precise measurement, adaptive stirring, and dynamic adjustment”. The specific steps are as follows:

1. Determine the dosage (core prerequisite)

Dosage range: The recommended dosage is 1%-3% of the total cementitious material. The specific dosage should be adjusted based on the concrete strength grade, cementitious material type (e.g., ordinary cement, mineral powder, fly ash), construction environment (temperature, humidity), and slump requirements.

2.Dissolution and Dilution (Flake-Specific Procedures)

Flake PCE must be dissolved into a liquid before adding to beton. Do not add solid flakes directly to the concrete mix. Dissolution Method: Slowly add the flake-form water reducer to room temperature water at a mass ratio of 1:5-10 (the concentration can be adjusted based on subsequent additions). Stir at a constant speed using a stirring device (such as an electric agitator) for 5-10 minutes until the solids are completely dissolved, forming a uniform, clear or pale yellow liquid free of sediment.

3.Addition Method and Mixing

Recommended order of addition: Use either the post-addition method or the simultaneous addition method, with the post-addition method being preferred (i.e., mixing sand, cement, and water for 30 seconds to form a mortar, then adding the diluted water reducer and continuing mixing for 60-90 seconds). This can increase the water reduction rate by 5%-10% and improve slump retention.

4. Construction Process Control

Slump Monitoring: Concrete slump must be tested immediately after leaving the concrete pump. If it does not meet construction requirements (e.g., the slump requirement for pumped concrete is 180 ± 20 mm), a small amount of diluted water reducer may be added within the specified range (not exceeding 20% of the original dosage). After addition, rapid mixing should be performed for at least 30 seconds.

Ⅵ. Precautions

1.Material Compatibility

Compatibility with Cement: Different brands and batches of cement (e.g., Portland cement, ordinary Portland cement) may vary in mineral composition (C3A and C3S content) and gypsum form (dihydrate gypsum, anhydrite), potentially leading to differences in the compatibility of water reducers.

2.Environmental and construction conditions

Temperature Effects:

High temperatures (≥30°C): Concrete slump loss accelerates, requiring an appropriate increase in the PCE dosage (by 10%-20%) or the addition of a retarding component (such as sodium gluconate). Transport and placement times should also be shortened, and the concrete mixture should be protected from direct sunlight.

Low temperatures (≤5°C): The PCE dissolves more slowly, requiring a longer mixing time (up to 30 seconds longer than at room temperature). If the temperature is ≤0°C, the mixing water should be heated (to 10-20°C) to prevent the PCE solution from freezing and becoming ineffective.

Storage Requirements:

Flake PCE should be stored in a dry, well-ventilated, and cool warehouse. Avoid moisture (moisture can cause caking and difficulty dissolving) and direct sunlight (high temperatures can degrade performance).

Dissolved liquid PCE should be used within 24 hours. Any unused portion should be sealed and stored to prevent prolonged exposure to air, which may cause deterioration.

Dissolved liquid PCE should be used within 24 hours. Any unused portion should be sealed and stored to prevent prolonged exposure to air, which may cause deterioration.

Ⅶ. Recommended Special Applications:

PCE water-reducing flake polycarboxylate superplasticizers are widely used in projects with stringent concrete performance requirements due to their ultra-high water reduction rate (25%-35%), strong compatibility with various cementitious materials and harsh environments, and the advantages of their solid form (low transportation and storage costs and long shelf life). They are particularly well-suited for concrete requiring high strength, high performance, high durability, and special construction conditions. Specific application areas are as follows:

1. High-strength and ultra-high-strength concrete projects

These projects require increasing strength by reducing the water-cement ratio (typically ≤0.30). PCE water-reducing flakes offer the precise water-reducing capability required to precisely meet these requirements. They are a core admixture for formulating concrete with strength grades C60 and above. Typical applications include:

Super-tall/high-rise building structures: Core tubes, frame columns, shear walls, and other load-bearing components in super-tall office buildings and hotels.

2. Prefabricated Components and Prefabricated Buildings

Prefabricated buildings place high demands on the dimensional accuracy, surface quality, and demolding efficiency of prefabricated components (such as prefabricated composite panels, prefabricated beams, and prefabricated staircases). PCE water-reducing sheet products, with their low water bleeding and high uniformity, offer a precise fit.

3. Specialty Mortars and Functional Concrete

PCE water-reducing flake products can be adjusted in dosage and compounded to meet the requirements of specialty mortars for high fluidity, high water retention, and high strength, as well as the specialized performance requirements of functional concrete.