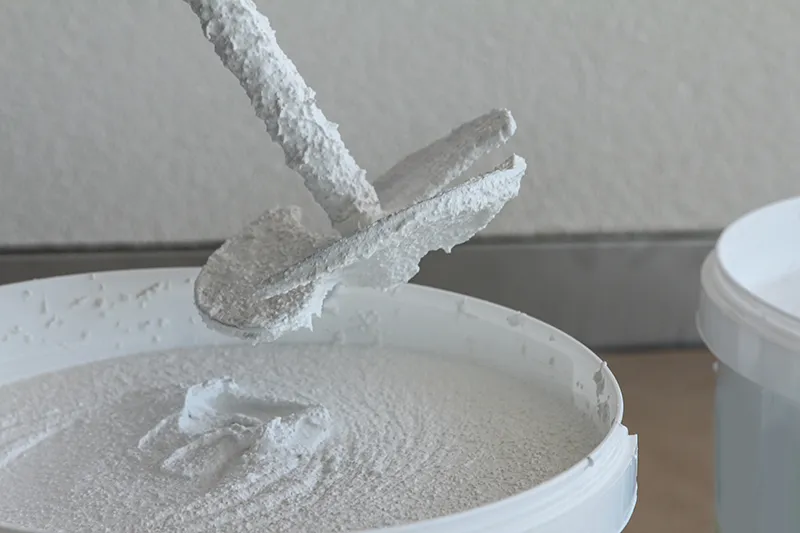

In the field of building kuru karışım harçlar, gypsum-based mortars are widely used due to their advantages such as fast setting, fire resistance, thermal insulation, and moisture-regulating capacity. However, they often face issues during construction like poor workability, susceptibility to sagging, and insufficient water retention leading to cracking. Selecting suitable additives is key to enhancing their performance, and starch ether is precisely one such efficient component that achieves remarkable results through synergistic effects.

Ⅰ. What is Starch Ether?

Starch ether, commonly such as hydroxypropyl starch ether, is a chemically modified polymer derived from natural starch through etherification. It is an efficient physical thickener and rheology modifier. In gypsum-based mortars, it primarily plays three core roles:

Thickening and Lubricating Agent: Significantly increases the consistency of the mortar while, through intermolecular lubrication, imparting excellent workability and smoother trowel application.

Anti-Sag Agent: Imparts good structural strength to the mortar, preventing sagging and slipping during application on vertical surfaces, effectively countering hollowing.

Water Retention Aid: Helps maintain water content by stabilizing the mortar system, providing a more stable environment for the hydration reaction of gypsum.

Ⅱ.What is the Synergistic Effect?

The so-called “synergistic effect” refers to the interaction between starch ether and other components in the gypsum mortar system (especially protein-based retarders), producing results superior to the simple sum of their individual effects.

Synergy with Retarders: Gypsum sets rapidly, often requiring the addition of protein-based retarders to extend workable time. Used alone, starch ether mainly improves workability. However, when combined, starch ether helps disperse and stabilize the retarder more uniformly within the system. This results in mortar with good workability, more controllable open time, and more stable later-stage strength development.

Synergy with Gypsum Particles: The long-chain molecules of starch ether can adsorb onto the surface of gypsum particles, forming a stable three-dimensional network structure. This structure not only traps more free water, preventing rapid water loss that leads to cracking, but also significantly enhances the cohesion of the mortar, thereby demonstrating excellent anti-sag performance.

Ⅲ.Core Performance Enhancements from Starch Ether

Adding an appropriate amount of starch ether to gypsum-based mortars (such as basecoat gypsum plasters, finish coat gypsum putties, etc.) brings about the following immediate improvements:

Superior Application Experience: The mortar becomes soft and smooth, allowing effortless application, significantly reducing labor intensity for workers and improving construction efficiency.

Elimination of Sagging and Hollowing: Even during thick-layer application on ceilings and vertical surfaces, the mortar adheres firmly, effectively improving construction quality and safety.

Reduced Cracking Risk: Improved water retention ensures sufficient hydration of the gypsum, resulting in a denser structure after hardening and greatly reducing shrinkage cracking and dusting caused by rapid water loss.

Optimized Pumpability: For machine-applied mortars, the addition of starch ether improves their rheology, reducing the risk of pipe blockage.

Ⅳ. Application Recommendations and Considerations

To fully leverage the synergistic effects of starch ether, attention must be paid to the following points:

Önerilen Dozaj: Typically, adding 0.02% – 0.05% starch ether in gypsum mortar is recommended (adjust based on product performance and formulation). Excessive addition may cause over-thickening and affect strength.

Dispersion is Key: It is essential to ensure starch ether is thoroughly and uniformly mixed with other raw materials (e.g., gypsum, retarder, sand) during the dry powder mixing stage to avoid lump formation.

Formulation Compatibility Testing: Due to variations in raw materials from different suppliers, laboratory and small-scale tests are imperative before full-scale production to find the optimal dosage point for your specific formulation.

Ⅴ. Conclusion

In summary, starch ether is far from being a simple thickener. Through its synergistic effects with the gypsum mortar system, particularly with protein-based retarders, it comprehensively enhances product performance across multiple dimensions including rheology, stability, and water retention. The scientific incorporation of starch ether into gypsum-based mortar formulations is a wise strategy for resolving construction challenges and improving the quality of the final finish, delivering significant technical and economic benefits for both manufacturers and contractors.