I. Understanding Mortar Strength

What exactly is mortar strength? It doesn’t just refer to the hardness of the material. Mortar strength is a combination of the following:

Compressive strength: the ability to withstand weight.

Bond strength: the strength of the bond between mortar and brick, block or tile.

Flexural strength: the ability of mortar to withstand bending or cracking forces.

A strong mortar mixture prevents tiles from falling out, walls from cracking, and repairs from being harmed, particularly when exposed to weather or structural stress. Understanding these factors is the first step toward increasing the performance of building materials.

II.Factors Influencing Mortar Strength

Cement-to-sand ratio: using too much sand or too little cement can cause the mortar to become brittle.

Water content: Excess water will make the mortar easier to apply, but it will significantly weaken the mortar when it dries.

Quality of mix: Uneven mixing can lead to weak areas and uneven curing of the mortar.

Environmental conditions: mortar that dries too quickly (especially in hot or windy climates) can lead to shrinkage and cracking.

Quality of materials: poor quality mortar, contaminated water or expired cement can damage the mix.

Optimizing these basic factors provides a solid foundation for the strength of the mortar and helps the additives perform better.

III. Tips to Improve Mortar Strength

Stick to the right mix ratio: Use the correct mix ratio for your specific application. A common mix ratio is 1 part cement to 3-4 parts sand, but this will vary from application to application. Tile adhesives often require a polymer-modified mixture.

Stick to the right mix ratio: Use the correct mix ratio for your specific application. A common mix ratio is 1 part cement to 3-4 parts sand, but this will vary from application to application. Tile adhesives often require a polymer-modified mixture.

Add water carefully: Always add small amounts and monitor the consistency. The less water, the less porous and stronger the mortar. The mortar should be easy to work with, not thin.

Add water carefully: Always add small amounts and monitor the consistency. The less water, the less porous and stronger the mortar. The mortar should be easy to work with, not thin.

Mix well: Use a mechanical mixer whenever possible to ensure even distribution.

Mix well: Use a mechanical mixer whenever possible to ensure even distribution.

Use clean materials: Avoid using sand and water that contain salt or dirt, as they can affect setting time and strength.

Use clean materials: Avoid using sand and water that contain salt or dirt, as they can affect setting time and strength.

During maintenance: Keep the mortar moist for at least 2-3 days after application. This helps the cement to fully hydrate and enhances the strength of the final product.

During maintenance: Keep the mortar moist for at least 2-3 days after application. This helps the cement to fully hydrate and enhances the strength of the final product.

Tip: In dry or hot climates, pre-wet the substrate and use a water retention additive to prevent rapid drying.

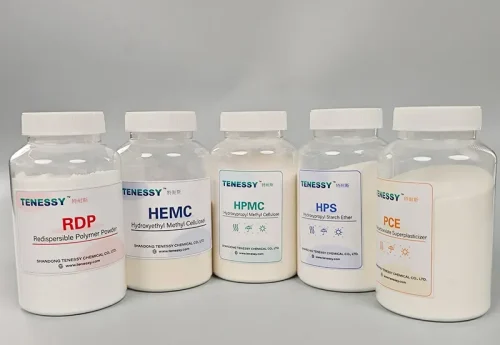

IV. Additives for Enhancing Mortar Strength

Construction additives are often essential. If properly selected, they can significantly improve the strength, workability and durability of mortar. Let’s look at the most effective choices:

1. Cellulose Ethers (HPMC/HEMC)

Key Benefits:

Better workability

Higher bond strength

Better curing in hot climates

2. Redispersible Polymer Powder (RDP)

Ideal Uses:

Tile adhesives

Exterior Exterior Insulation Systems (EIFS)

Repair mortars and flexible plasters

3. Superplasticizers

Effect: Higher compressive strength and better workability.

All of these additives are available in different grades, so it is critical to work with a reliable supplier to select the right formulation for your specific project.

V. How to choose the right additive for your mortar

Not all additives are suitable for all constructions. Here is how to make the right choice:

1.Consider the application

Tile adhesives: prioritize bonding, flexibility and anti-slip properties.

Plastering mortars: need additives that improve water retention and ease of spreading.

Masonry mortars: focus on bond strength and ease of application.

Waterproofing mortar: Generally used in kitchens or toilets, waterproofing type additives are needed.

2. Consider environmental conditions

Hot, dry or windy climates can cause mortars to dry out too quickly. Choose additives with better water retention to avoid cracking or shrinkage.

3. Balance cost and performance

While quality additives may have a higher upfront cost, they can save money in the long run by reducing rework, repairs and breakdowns.

4. Choosing the right supplier

Trustworthy suppliers don’t just offer products, they need to provide technical support, help you optimize your formulations and offer quality assurance.

VI. Frequently Asked Questions

Q: Can I just add more cement to make the mortar stronger?

Q: How do I know how much HPMC or RDP to use?

Q: Can I combine different additives?

Q: Will additives delay setting time?

VII. Conclusion

Contact us today for free technical support or samples of additives customized to your application.