I.Blistering of wall putty

Air bubbles are generated during the construction process and after a period of time, the surface of putty blisters.

1.Causes of blistering

- One time construction putty layer is too thick, more than 2mm.

- Workers worked for a while until uneven mixing produced the surface of the bursting bubbles, since the slurry contained powder particles that dissolved too late.After they completed construction, a large amount of water absorbed, dissolved, and expanded, forming bursts.

- The grass-roots level is too rough, with tiny holes. Putty when scraping the holes in the air compression, after the air pressure rebound to form bubbles.

- The grass-roots level is too dry, and the water absorption rate is too high, which is easy to cause the top layer putty bubbles.

- Too much cellulose ether added will also cause bubbling.

2.Solution

- Avoid scraping the putty layer too thick at one time. It is recommended to apply the putty layer thickness of not more than 2mm each time, and complete the construction in several times. After applying each layer of putty, you must wait until the previous layer is completely dry before applying the next layer. This will ensure that the surface is firm.

- Ensure that the putty powder is evenly mixed with water. Mix using a mechanical mixer to ensure that there are no undissolved particles in the slurry. Mix for sufficient time to ensure that the putty slurry is uniform and smooth to avoid air bubbles and dissolution caused by uneven mixing.

- Before construction, the base should be adequately treated. Fill the holes and cracks of the grass-roots level with putty or interfacial agent to ensure that the surface of the grass-roots level is flat and smooth. By sanding and cleaning the grass-roots level before scraping putty, remove floating dust and debris to ensure good adhesion.

- Before construction, use a sprayer to gently dampen the base layer to reduce the water absorption of the base layer. During construction, avoid high temperature, strong wind or too dry environment.

- Control the amount of cellulose added. Too much cellulose will cause the putty paste to be thick and increase the possibility of bubble generation. Use the appropriate amount of cellulose added to improve the adhesion and workability of the putty and avoid blistering problems caused by adding too much.

| Weight (kg) | Raw Materials |

| 300 | White or Gray Silica Fume Cement |

| 220 | Quartz Powder (160-200 mesh) |

| 450 | Heavy Calcium (0.045mm) |

| 6月10日 | Redispersible Polymer Powder(RDP) |

| 4.5-5 | Cellulose Ether HPMC (100000) |

| 3 | White Wood Fiber |

| 1 | Polypropylene Fiber (3mm) |

| 1000.5 |

II. Powdering of exterior wall putty

After the construction is completed and the putty is dry, touch the surface with your hand, and there is powder falling off.

1.Causes

- High water absorption rate of grass-roots level causes the putty to dry very fast without sufficient moisture for curing.

- Exterior wall putty powder, finish when the coating is relatively thin, in the summer high temperature, the moisture volatilization is very fast, the surface layer fails to sufficient moisture for curing, and thus easy to fall off the powder.

- Related to the amount and quality of cellulose added, this is mainly related to the water retention rate, cellulose water retention rate is low, gray calcium hydration time is not enough.

- Improper polishing treatment.

2.Solution

- Before the construction of the grass-roots level, the use of interfacial agents or sealers to reduce the water absorption rate of the grass-roots level, to ensure that the putty can be fully cured in the appropriate time. For particularly dry grass-roots level, it is recommended that the grass-roots level be moistened with water first to reduce the risk of water evaporating too quickly.

- Treat the substrate before construction, using an interface agent or sealant. This treatment can reduce the water absorption of the substrate and ensure that the putty can fully cure within an appropriate time.For particularly dry substrates, it is recommended to wet the substrate with water first to reduce the risk of water evaporating too quickly.

- The use of high quality cellulose, especially TENESSY®HPMC with high water retention, helps to prolong the hydration time of the cement and reduces the phenomenon of de-powdering.

- Avoid polishing or over-treating the putty surface until it is completely dry, giving the putty enough time to finish curing.

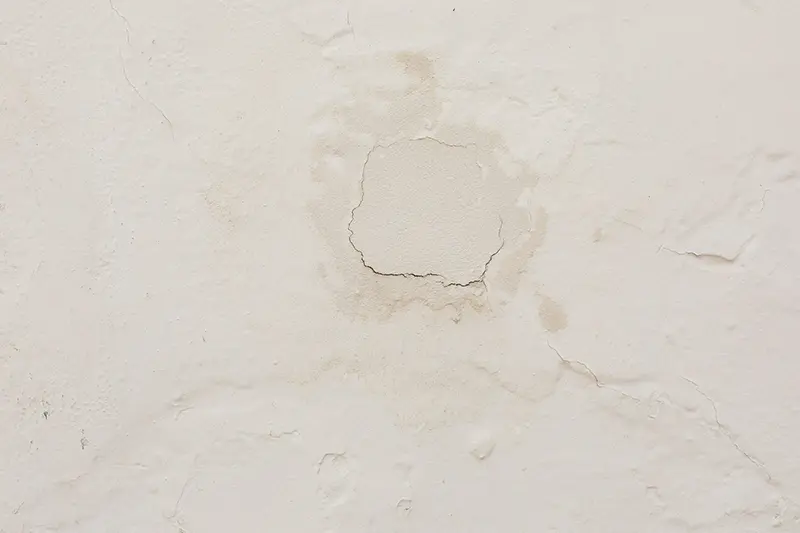

III. Yellowing and cracking of putty on external walls

Putty construction after a period of time, cracking.

1.Causes

- This is related to the addition of gray calcium, more gray calcium addition, resulting in putty powder dry hardness increase, only hardness without flexibility will be easy to crack, especially when subjected to external forces will be more likely to crack.

- The bottom layer of putty is not dry over the surface, the surface layer first dry, while the inner layer continues to dry in the process, resulting in different degrees of drying and shrinking between the layers, resulting in cracking.

- Construction is too thick, the internal drying slower, the surface drying faster, also easy to cause cracking.

2.Solution

- Control the amount of gray calcium added, avoid overuse, and maintain a proper balance of hardness and flexibility.

- Ensure that the bottom layer putty is completely dry before proceeding with the construction of the surface layer to avoid cracking caused by the difference in drying and shrinking between layers.

- Avoid applying putty too thick at one time, work in layers, apply each layer thinly and evenly to ensure a consistent drying rate and reduce the occurrence of cracks.

- Someone needs to shovel out the cracked putty. If the cracks are not too big, flexible putty can also be used for the first construction, and then the construction is carried out according to the standardized construction method.

IV. Wall Putty Alkalization

Putty alkali, mainly because the putty after scraping has not been hydrated into the water.

1. Causes

The salt and alkali in the materials or walls seep from the micropores of the putty to its surface when the construction crew does not fully hydrate the putty during humid weather. As the water evaporates slowly, the alkali reacts with the carbon dioxide in the air to form white calcium carbonate precipitation, which causes alkali flooding.

2.Solution

- Avoid construction in wet weather to ensure that the putty has enough time for hydration reaction after construction. If construction is necessary, use suitable protective measures, such as sun screen, to prevent the putty surface from premature exposure to moisture.

- Ensure that each layer of putty is completely dry before proceeding to the next step in the construction process to avoid too rapid evaporation of moisture causing alkali migration to the surface.

V.Difficulty in applying wall putty

Wall putty application process is more difficult, scraping is more laborious, because the putty added cellulose viscosity is too high, general wall putty powder is recommended to add viscosity of 80000-100000 HPMC.

VI.Putty powder becomes thinner after adding water

Cellulose as a thickener water retention agent application, due to the thixotropy of cellulose itself, the addition of cellulose in the exterior wall putty powder also led to the putty with water to produce a thixotropy. This thixotropy results from the breakdown of the loosely bonded structure of the components in the putty powder. This structure arises at rest and breaks up under stress. This means that the viscosity decreases under agitation and recovers at rest.

VII. Choosing the right cellulose supplier

TENESSY®HPMC has excellent properties in wall putty:

1. Improvement of water retention

Cellulose has good water retention properties, which can effectively slow down the evaporation of water and help putty keep enough water during drying. This helps the putty layer to fully solidify, avoiding the problems of powder removal and cracking caused by too fast drying.

2. Enhance bonding force

Cellulose in the wall putty plays a role in increasing adhesion, enhance the adhesion of putty and grass-roots level, to ensure that the putty layer firmly attached to the wall surface, to avoid putty fall off due to wall movement or external forces.

3. Enhance crack resistance

Cellulose helps the putty layer to adapt to the small changes of the grass-roots level by enhancing the flexibility of the putty and reducing the risk of drying and cracking. Especially for exterior putty, cellulose can increase its adaptability to temperature and humidity changes and prevent cracks.

TENESSY suppliers can provide suitable products according to customers’ formulations.

VIII. Summary

During the construction of exterior wall putty, problems such as blistering, de-powdering, yellowing and cracking, alkali flooding, etc. often plague builders and customers. Understanding the causes of these problems is the first step to solve them, and through scientific construction methods and proper material selection, these problems can be effectively avoided.