Ⅰ.What is the "Open Time" of Tile Adhesive? Why is it Crucial?

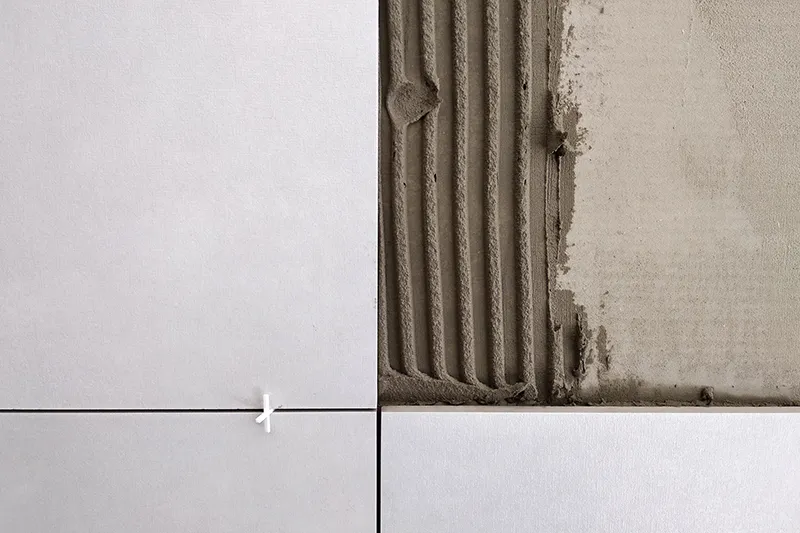

In tile installation, “open time” refers to the period after the tile adhesive is troweled onto the substrate, during which effective tile fixing can still be performed before its surface dries out and loses its bonding capability.

Short Open Time: Workers laying tiles over a large area may not have enough time to adjust tiles. Tiles laid later might have already lost moisture, leading to a significant decrease in adhesive strength and ultimately causing hollow tiles and detachment.

Long Open Time: Can delay the initial setting time, impacting the construction schedule, though this may not be the primary concern in well-ventilated environments.

Therefore, excellent and consistent open time is key to ensuring tile installation quality and improving construction efficiency. So, what factors determine open time, and how can we scientifically extend it?

Ⅱ.Three Core Factors Affecting the Open Time of Tile Adhesive

Environmental Factors: High temperature, low humidity, and strong wind accelerate water evaporation, drastically shortening open time.

Substrate Factors: Porous, dry substrates (e.g., aerated concrete blocks) rapidly absorb water from the mortar.

Formulation Factors (The Most Critical and Controllable Factor): The design of the tile adhesive formulation, especially the selection of the water retention component, is fundamental in determining open time.

Ⅲ. How to Effectively Extend Open Time Through Formulation Design?

The core of the solution is: Under uncontrollable environmental conditions, slow down the evaporation and loss of water from the mortar by optimizing the formulation, buying more time for tile fixing.

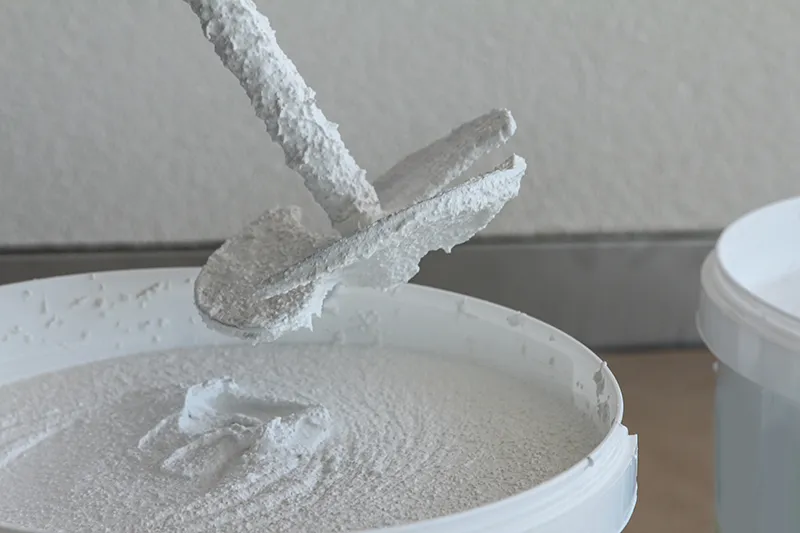

1. Key Factor: High-Quality Hydroxypropyl Methyl Cellulose

Hydroxypropyl Methyl Cellulose Ether (HPMC) is the “water retention master” in tile adhesive and is the most critical component for extending open time.

Mechanism: HPMC dissolves in water to form a transparent colloidal film that effectively locks in moisture. This film significantly slows down the rate of water loss to the air and the substrate, thereby extending the mortar’s workable time.

How to Select HPMC to Optimize Open Time?

Viscosity Selection: Higher viscosity is not always better. Excessively high viscosity (e.g., above 200,000 mPa·s), while good for water retention, can affect the mortar’s wettability and application feel. For tile adhesives, medium viscosity (40,000 – 100,000 mPa·s) HPMC is typically chosen to achieve the best balance between water retention and workability.

Degree of Etherification and Uniformity: Select HPMC products with high degree of etherification and uniform particle size. Such products dissolve faster, provide more stable water retention performance, and offer a smoother, more predictable open time curve. Dosage: Within reasonable cost limits, appropriately increasing the HPMC dosage is a direct and effective method.

2. Auxiliary Strategies: Synergistic Effects with Other Additives

Adding Polvere polimerica ridisperdibile (RDP): RDP can form a polymer film within the mortar. This film not only enhances the final bond strength but also assists HPMC in providing some water retention and thickening effect, positively contributing to maintaining open time.

Using Polvere idrofobica di silicone (SHP): In tile adhesives requiring flexibility and anti-sag properties, adding a small amount of Silicone Hydrophobic Powder can form a hydrophobic film on the mortar particles, slowing down the rate of water absorption by porous substrates, indirectly supporting the extension of open time.

Ⅳ.Professional Advice from TENESSY Chemical

As a professional supplier of construction chemicals, TENEREZZA advises addressing the issue from a systematic perspective:

Accurate Diagnosis: First, determine whether the insufficient open time is a formulation problem or an on-site construction environment issue.

Formulation Optimization: The core is to evaluate and upgrade the Hydroxypropyl Methyl Cellulose(HPMC) you are currently using.

On-site Guidance: Even with excellent products, correct application is essential. Workers should be instructed to:

- Avoid construction in direct sunlight or windy conditions.

- Avoid troweling too large an area at once; the area should match the expected open time.

- Pre-wet highly absorbent substrates (no free water).

Ⅴ.Conclusion

Extending the open time of tile adhesive is not simply a matter of “adding more of something,” but rather a systematic art of formulation balance. The core lies in using high-quality Cellulose Ether (HPMC) to build a robust “water retention system,” supplemented by other additives and correct construction guidance.

TENEREZZA, leveraging years of R&D and production experience in the etere di cellulosa field, provides you with a full range of HPMC e Polvere di polimero ridisperdibile products. Supported by a professional technical team, we can offer tailored solutions to help you thoroughly resolve short open time issues in tile adhesives and manufacture more competitive products.