Hydroxyethyl cellulose is a non-ionic, water-soluble polymer that is now widely used in many industries due to its excellent rheological ability, thickening ability and compatibility with many different formulations.HEC Hydroxyethyl cellulose in oil drilling can optimize drilling, cementing, hydraulic fracturing and other aspects.

Importance of HEC in Oilfield Applications

The oilfield industry requires specialized materials that can withstand high pressures, extreme temperatures, and a wide range of chemical conditions. TENESSY® Hydroxyethyl Cellulose HEC can be used as an additive to non-dispersible brine bentonite clay slurries in oil drilling. This reduces water loss and increases viscosity without increasing gel strength.

In addition, using HEC in drilling muds improves clay dispersion in the well and prevents well collapse. HEC’s versatility and environmental benefits make it a key component of modern oilfield technology.

TENESSY® HEC for oil drilling applications

HEC for drilling fluids

Drilling fluids, also known as drilling muds, are used to cool the drill bit, stabilize the wellbore and transport cuttings to the surface. Ensuring the safety and efficiency of drilling operations requires maintaining the proper balance of fluid properties.

Drillers commonly utilize hydroxyethyl cellulose-containing drilling fluids for hard rock drilling and unique scenario drilling, including high and low shale formations, pressure anomalies, excessive water loss, and circulating water leakage management. Large borehole and open hole drilling operations also benefit from it. Operators can use HEC in drilling mud to chill the iron filings and drill cuttings and bring them to the surface, increasing the mud’s ability to carry rock because of its thickening, suspending, and lubricating qualities. Manufacturers produce hydroxyethylcellulose as a non-ionic, water-soluble polymer. Many industries currently use it due to its excellent rheological properties, thickening ability, and compatibility with various formulations. In the oilfield industry, HEC plays a vital role in optimizing drilling, cementing, and hydraulic fracturing.

Drillers can also use hydroxyethyl cellulose in drilling muds as a non-fermentable protective gel for oil well treatments and for assay work at high pressures (20 MPa) and temperatures. Workers use HEC as a thickening and cementing agent in oil well workover fluids. It helps to provide a clarified solution with a low fixed content, which greatly minimizes damage to the well structure.

It was once used as a well hole expanding and carrying sand solution, which was effective and put into practice. The use of hydroxyethyl cellulose can also greatly improve the mud’s loss-of-filtration properties and substantially increase the stability of the mud.

HEC for well completion and workover

To finish well construction and prepare the well for production, operators utilize well completion fluids. Workers use workover fluids to repair or maintain wells. Many oilfield activities use high salinity brines as base fluids, and TENESSY® HEC performs well with a variety of brine solutions to provide reliable performance in these high salinity conditions.

HEC is formulated as a low-solids completion fluid that prevents clay particles from clogging reservoir voids as it approaches the formation, and the water-loss-reducing property prevents large quantities of water from entering the formation from the mud to ensure the productivity of the formation.

TENESSY® HEC reduces the friction of the mud, which in turn reduces pump pressure and power consumption. Its excellent salt solubility also ensures that no precipitate is precipitated when acidizing the well.

HEC for hydraulic fracturing fluid

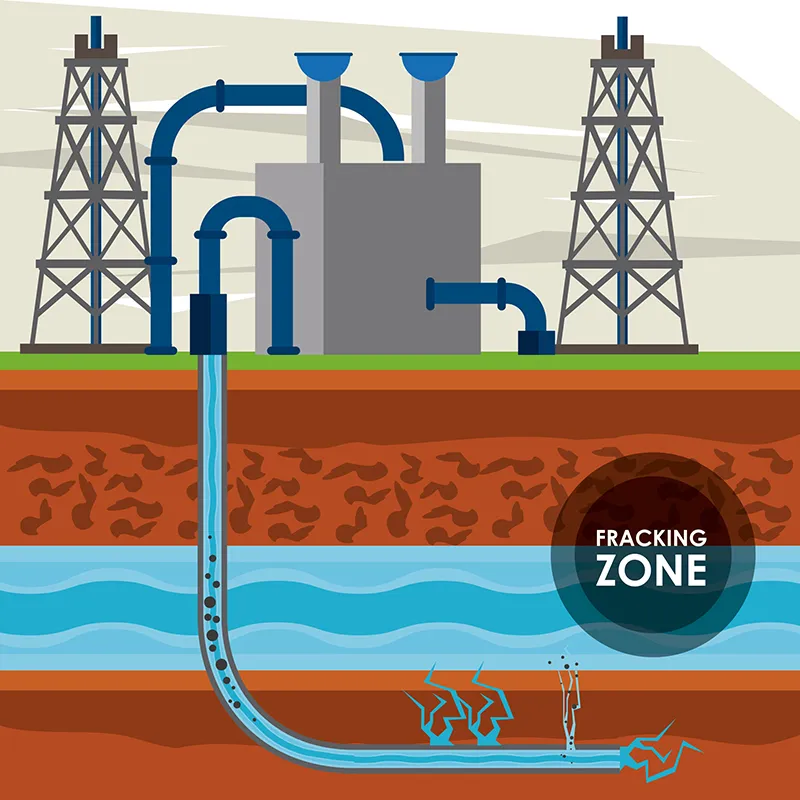

During hydraulic fracturing, companies inject a high-pressure fracturing fluid into the rock to create fractures. This action allows the proppant to suspend and move deeper into the fracture. Due to its low toxicity and biodegradability, many choose hydroxyethyl cellulose as a more environmentally acceptable alternative to conventional chemical additives in fracking fluids.

In fracturing fluids, TENESSY® HEC increases viscosity and can fracture oil wells without affecting the formation or clogging fractures. Water-based fracturing fluids made with HEC are essentially residue-free after liquefaction, making them particularly suitable for formations with low permeability where backdraining residue is not possible.

HEC can avoid viscosity loss and rupture of oil formation due to high downhole temperature, and still have better effect in wells higher than 371°C. HEC does not easily corrupt and deteriorate downhole, has low residue, and will not block the oil circuit or cause downhole pollution. Studies have shown that HEC performs best when comparing the effectiveness of CMC, MC, HPC, and HEC as fracturing fluid components.

TENESSY offers the most suitable product models for the oilfield industry:

| HEC Model | Viscosity (25°C,Brookfield,mpa.s) | Viscosity (20℃,NDJ-1) | Application |

| 1%water solution | 2%water solution | ||

| NC100KH | 3600-5000 | 85000-100000 | Oil well repairing fluid, petroleum cementing and other oil field fields, exterior wall paint, real stone paint, textile printing and dyeing, papermaking. |

Summary

Hydroxyethyl cellulose is a highly effective and versatile additive for oilfield applications, and is a key component of the petroleum industry for its ability to increase viscosity, control fluid loss, and stabilize formations.