In this article, we’ll answer these questions and help you understand why white cement is an excellent choice for putty for walls, especially when paired with the right additives.

I.What is White Cement?

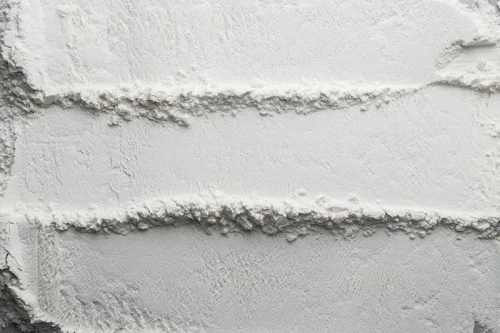

White cement is a type of Portland cement, made using raw materials with very low iron and magnesium content. This gives it its signature white color, as well as high brightness and smoothness.

Unlike grey cement, white cement is specially processed to have:

High purity

Excellent surface finish

Better aesthetics

In putty construction, white cement is often used as the core binder. It forms the backbone of the product, ensuring hardness, durability, and a clean surface that enhances the topcoat of paint.

II.The Role of White Cement in Wall Putty Formulas

In a typical cement putty formula, white cement plays multiple roles:

Structural Strength: It binds the powder and fillers together, forming a hard, durable layer once dried.

Whiteness: It gives the putty its bright white color, allowing paints to show their true shades with fewer coats.

Moisture Resistance: It prevents dampness and flaking of paint by acting as a protective barrier.

Smooth Application: It helps achieve a smooth, even surface that’s easy to paint.

By choosing white cement as the main component in your putty for walls, you ensure consistent quality and long-lasting wall protection.

III.Key Benefits: Why Use White Cement in Putty for Walls?

1.Clean and Bright Surface

White putty made with white cement provides a bright and uniform base. This enhances the appearance of your final paint coat and reduces paint consumption. It’s perfect for modern interiors that require a premium finish.

2.Easy Application and Better Workability

3.Crack Resistance and Durability

Thanks to its strength, putty cement with white cement resists cracking, chalking, and peeling over time. It also withstands environmental stress better than gypsum-based alternatives.

4.Excellent Filling Power

IV.Cement Putty vs Wall Putty: What’s the Difference?

This is a question many customers and even some manufacturers often ask: Cement putty vs wall putty – are they the same?

Cement putty refers broadly to any putty that uses cement (white or grey) as the main binder. It is strong, moisture-resistant, and suitable for both interior and exterior use.

Wall putty, on the other hand, is a more general term that includes cement-based putties as well as gypsum or acrylic-based ones.

So when we talk about white cement putty, it combines the best of both worlds: the strength of putty cement and the smoothness required for premium wall putty finishes.

V.What Goes Into a White Cement Putty Formula?

| Raw Materials | Content | Function |

| White Cement | 30-50% | Main adhesive, determines the strength and whiteness of putty |

| Calcium Carbonate | 30-50% | Fillers to improve smoothness and spreadability |

| HPMC/HEMC | 0.2-0.5% | Controllable water retention and construction time |

| Redispersible Polymer Powder | 1-3% | Increases flexibility and prevents cracking |

| Other Additives | Defoamer, Wood Fiber | Improved Stability |

This combination gives you a balanced, reliable formula suitable for both new walls and renovation work.

VI.“Wall Putty Near Me” vs Custom Formulas: What’s Better for You?

Many buyers search online for “wall putty near me” hoping to find local supply. But as a manufacturer, relying on generic off-the-shelf products limits your flexibility.

By developing your own customized formulation of white cement and premium additives, you can:

Control product quality

Adjust performance for local climate (humidity, temperature)

Differentiate your brand

Save on costs by using bulk raw materials

VII.Conclusion

To sum up, white cement is more than just a color enhancer – it is the core material that gives putty its strength, beauty, and long-lasting performance.For putty powder manufacturers looking to develop premium products, choosing white cement and the right additives can set your brand apart in a competitive market.

Need help formulating your perfect white putty? Contact us today for expert advice, high-quality materials, and customized solutions that suit your local market.