1.Water-Based Paints and Coatings

One of the most prominent uses of hydroxyethyl cellulose is in water-based paints and coatings.

Viscosity control: HEC regulates the viscosity of coatings to ensure uniform application and prevent sagging.

Stabilization: It helps to disperse pigments and fillers to prevent settling.

Film Formation: HEC improves the quality of dried coatings, providing a smooth surface and better durability.

Application Examples:

HEC is often used in architectural, industrial and protective coatings that require better consistency and appearance.

2. Daily Chemical Detergents

In household and industrial cleaning formulations, hydroxyethyl cellulose ensures product stability and user experience.

Key features in cleaning products:

Thickener: HEC creates the viscosity needed in shampoos, liquid detergents and hand soaps, enhancing texture and ease of use.

Stabilization: Prevents phase separation and ensures homogeneity in multi-phase formulations.

Mild Performance: Non-toxic and skin friendly, meeting the needs of personal care and environmentally friendly cleaning products.

3. Oil Drilling and Extraction

The importance of HEC in oil drilling:

Fluid Loss Control: During the drilling process, the drilling fluid may penetrate into the formation and cause filtration loss. HEC is able to form a dense filter cake on the surface of the formation, reducing the amount of filtration loss of the drilling fluid, protecting the oil and gas formation, reducing the damage to the formation, and improving the success rate of drilling.

Thickening and Rheology Enhancement: HEC has excellent thickening ability, which can regulate the viscosity of the drilling fluid, making it more effective in carrying and suspending rock cuttings during the drilling process, thus reducing the wear and tear of the drilling tools and improving the drilling efficiency. In addition, HEC’s regulation of rheology helps to maintain the stability of the drilling fluid, which exhibits consistent performance at different temperatures and pressures.

Thermal Stability: Oil drilling is often conducted at high temperatures and high salinity, but HEC is able to maintain its stability under such extreme conditions, showing strong resistance to salt and high temperatures. This makes HEC an important additive for deep and ultra-deep well drilling fluids.

4.Textile Industry

5. Ceramics Manufacturing

In ceramics, the properties of hydroxyethyl cellulose can improve productivity and finished product quality.

Role in ceramic applications:

Binder and thickener in ceramic blanks: HEC provides the necessary viscosity for ceramic glazes and suspensions, and can improve the plasticity and strength of blanks, preventing cracks or deformation during the molding process.

Suspending agent in glazes: Used as a suspending agent in ceramic glazes, HEC effectively prevents glaze settling and ensures uniformity and stability of the glaze during coating.

Improved processability: Ensures a smoother molding process and better adhesion of the ceramic coating.

Stability: HEC prevents the ceramic paste from settling and maintains consistency.

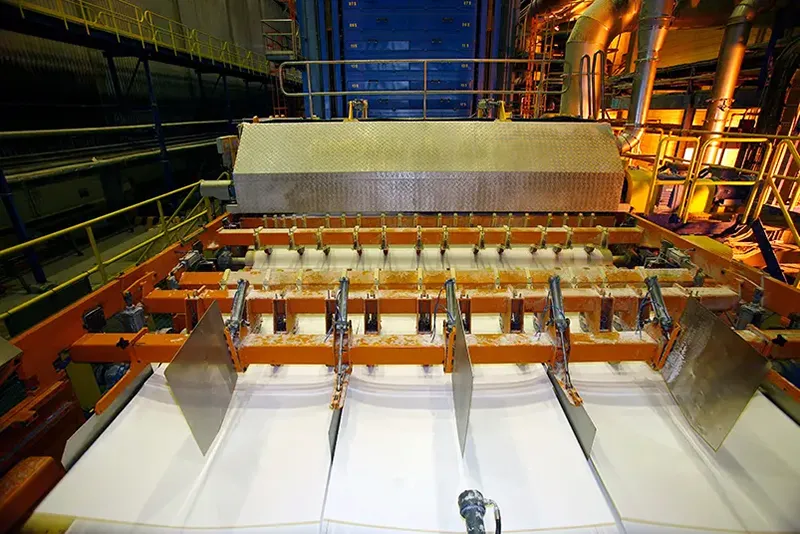

6. Paper Industry

The paper industry utilizes hydroxyethyl cellulose to improve product quality and process efficiency.

Contribution to paper making:

Coating formulations: HEC improves the rheological properties of paper coatings, resulting in improved printability and surface quality.

Sizing and Strength: It improves water resistance and tensile strength of finished paper.

Retention aid: HEC ensures better retention of fillers and fibers, reducing waste and improving yield.

7. Pharmaceutical Industry

The pharmaceutical industry values the safety and versatility of hydroxyethyl cellulose in drug formulations.

Applications in Pharmaceuticals:

Thickener: HEC provides the desired consistency in syrups, suspensions and topical formulations.

Stabilizers: It ensures uniform dispersion of the active ingredient, thereby enhancing the efficacy of the drug.

Controlled release: Using HEC in extended-release formulations ensures a steady release of active ingredients over time.

8. Why choose hydroxyethyl cellulose for your application?

Due to its superior qualities, hydroxyethyl cellulose has a wide range of uses across a variety of industries:

Environmentally friendly: HEC is derived from natural cellulose and meets sustainability goals.

Non-toxic: It is safe to use in a wide range of products from food-grade to pharmaceutical-grade formulations.

Versatile: It has broad compatibility with a wide range of systems, making it a versatile solution.

9. Summary

Hydroxyethyl cellulose continues to revolutionize the industry by providing advantages in viscosity control, stability and functionality. Its wide range of applications in aqueous coatings, household chemical cleaning, oil drilling, textiles, ceramics, paper and pharmaceuticals emphasize its indispensability in modern manufacturing. If you’re considering integrating hydroxyethyl cellulose into your manufacturing process, understanding the many uses of cellulose can help you optimize formulations, reduce costs and meet industry standards.

Need expert advice on hydroxyethyl cellulose applications? Contact us to explore customized solutions for your industry needs.