Bonding Mortar Additive

- Home

- »

- Industries & Applications

- »

- Drymix Mortar

- »

- Bonding Mortar Additive

Bonding Mortar

Bonding mortar is a specialty mortar for bonding tiles, stone or other building materials. It consists of high quality cement, selected aggregates and a variety of bonding mortar additives such as HPMC and RDP. It provides a long-lasting bond between different substrates and ensures that the material is solid and does not fall off.

Types and Effects of Bonding Mortar Additives

Common additives in bonding mortars include:

- Thickening and water retention: Prevents mortar from cracking and peeling as it dries.

- Enhances workability.

- Improves adhesion.

- Enhances bond strength.

- Improved crack and impact resistance.

- Improved water and seepage resistance.

- Suitable for construction on vertical surfaces to prevent slipping.

- Improves workability and spreadability

Advantages of Bonding Mortar Additives

- Enhanced bonding - Improve the adhesion between mortar and tiles and substrates, preventing hollowing and peeling.

- Improve construction performance - Improve water retention and fluidity of mortar, enhance spreadability and construction efficiency.

- Improved flexibility and crack resistance - Adapts to temperature and humidity changes in different environments, preventing cracking and peeling.

- Enhanced water and seepage resistance - Suitable for wet environments such as kitchens and bathrooms, ensuring a long-lasting and stable bond.

Main Applications for Bonding Mortars

Tile and Stone Paving

Bonding mortar is widely used to paste tiles, marble, granite and artificial stone. Suitable for wall and floor construction. Ensure that the material adheres firmly and prevents drumming and peeling.

Exterior Insulation System (EIFS)

In EIFS, bonding mortar is used to adhere the insulation boards to the building wall. It also enhances the overall solidity and durability of the system.

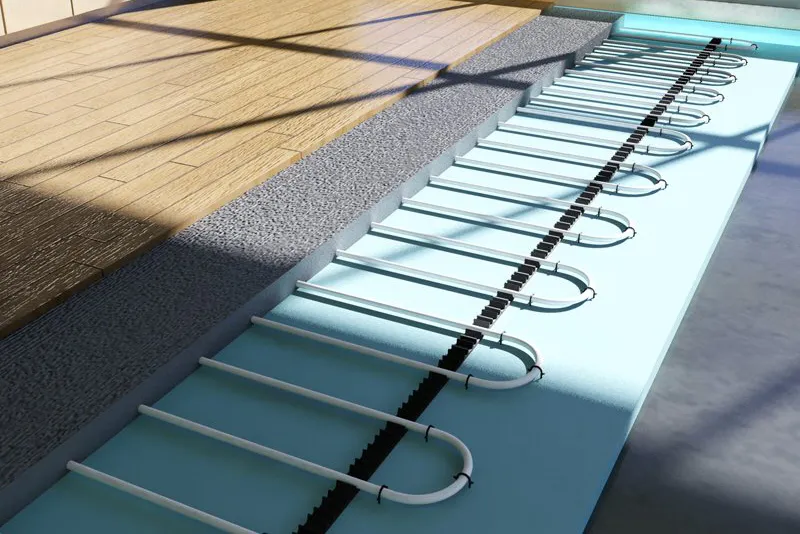

Underfloor Heating System

Bonding mortar is used to fix heating pipes and protective layers in underfloor heating systems. It ensures the structural stability of the system and prevents cracking caused by thermal expansion and contraction.

Repair and Reinforcement

As a high-strength bonding material. Bonding mortars are also commonly used for repairing and reinforcing concrete structures to improve their overall performance.

FAQs

Q1: What is the recommended dosage of HPMC for bonded mortar additives? What are the effects of overuse?

The recommended dosage is 1%-3% by weight of the dry powder of the bonded mortar (specific needs to be based on the application formula). Excessive use may lead to shortening of mortar opening time, decrease in strength or cracking. It is recommended to carry out small sample test first to confirm the effect before using in bulk.

Q2: Is the additive compatible with all brands/types of bonding mortar?

Additives are compatible with cement-based and polymer-modified mortars, but avoid mixing with mortars containing strong acids or organic solvents. It is recommended to carry out a compatibility test first: take a small amount of mortar + additive and observe whether there are any lumps, delamination or abnormal solidification.

Q3: Why do bonding mortars tend to fail in wet environments?

Bonding mortars tend to fail in wet environments, usually due to insufficient water resistance or high water absorption of the substrate, resulting in reduced adhesion. Adding RDP can enhance the water resistance and flexibility of the mortar, which can reduce the water absorption of the base and improve the bonding effect.