The Impact of HPMC Dosage on the Bonding Strength of Tile Adhesive: The Key Role of Scientific Proportioning

In modern architectural decoration engineering, tile adhesive, as the core material for tile installation, directly determines the safety and durability of the cladding system. With the advancement of building material science, the use of additives has become a crucial means of improving the performance of tile adhesives.

The Profound Impact of Redispersible Polymer Powder on Mortar Hardening

This article will systematically elaborate on its mechanism of action, the multidimensional enhancement of the hardening process and final performance, demonstrating its outstanding value in modern construction.

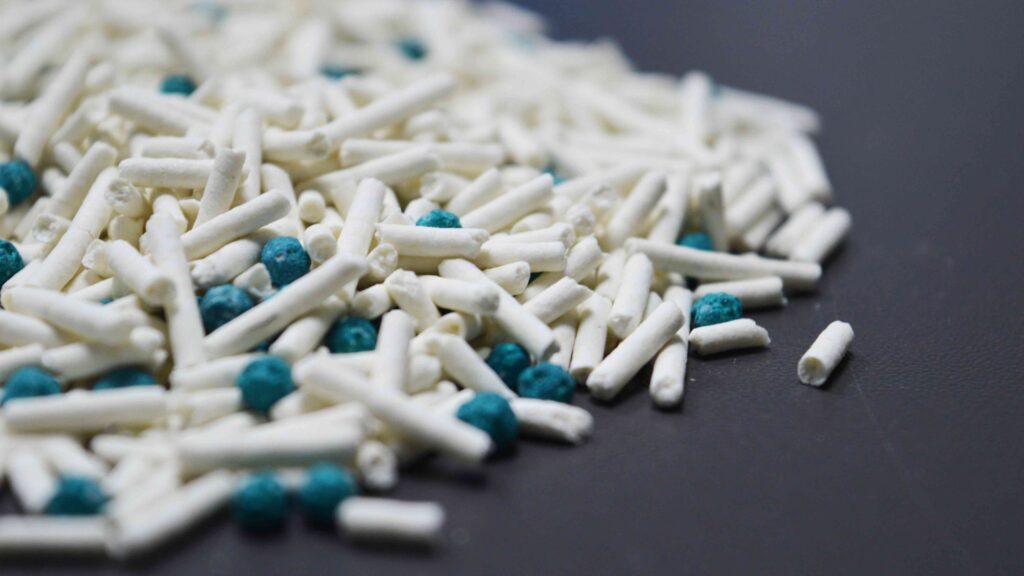

CMC in Cat Litter: An Innovative Material Enhancing Pet Life Quality

In recent years, a material called CMC (sodium carboxymethyl cellulose) has quietly entered the cat litter field, bringing about delightful changes. This article will delve into the application of CMC in cat litter, analyzing how it enhances the feline toileting experience and home cleaning convenience.

Insulation and Decorative Integrated Panels: Redispersible Polymer Powder Ensures Firm Interlayer Bonding

In the coatings industry, the primary functions of HEC include: providing excellent rheological properties for application, preventing pigment settling, improving storage stability, extending open time, and controlling splashing and sagging.

Hydroxyethyl Cellulose (HEC) in Coatings

In the coatings industry, the primary functions of HEC include: providing excellent rheological properties for application, preventing pigment settling, improving storage stability, extending open time, and controlling splashing and sagging.

HPMC: High-Performance Additive in Ceramic Processing

In ceramic production, precise process control directly determines the quality and yield of the final product. HPMC (Hydroxypropyl Methylcellulose), as a key functional additive, is providing multidimensional and systematic solutions for modern ceramic manufacturing with its unique technical properties.

High Viscosity vs Low Viscosity Polyanionic Cellulose: Key Application Differences in Drilling Fluids, Coatings, and Food

Polyanionic Cellulose (PAC), as a versatile water-soluble polymer, has a viscosity grade selection that directly affects the performance, production efficiency, and economic viability of the final product.

How Do HPMC, RDP and Polypropylene Fiber Work in Thermal Insulation Mortar?

This article provides a clear comparison between sand-based and sand-free thermal insulation mortars and explains how these three additives function individually and synergistically, offering practical guidance for manufacturers aiming to improve product performance and consistency.

The Key Role of HPMC and Retarders in Gypsum Formulations: Optimization and Application

In modern construction, gypsum-based materials have become indispensable due to their efficiency, smooth finish, and sustainability. From interior wall plasters to self-leveling compounds and joint fillers, gypsum products are widely used for both residential and commercial projects.

Putty Powder Bubbling and Cracking? The Key Lies in Deep Optimization of Cellulose Ether Formula

Bubbling and cracking after putty powder application are common stubborn issues that trouble many painters and homeowners. These problems not only affect wall aesthetics but may also indicate deep quality hazards.