I. What is EIFS?

EIFS, or Exterior Insulation Finishing System (also known as etics or etics system), is a sophisticated, multi-layered cladding solution for exterior walls. Unlike traditional materials, EIFS exterior systems provide continuous exterior insulation, significantly boosting a building’s energy efficiency.

Understanding the definition of EIFS is key: it’s a non-load bearing, composite EIFS wall system designed to provide insulation, weather resistance, and aesthetic appeal in one integrated package.

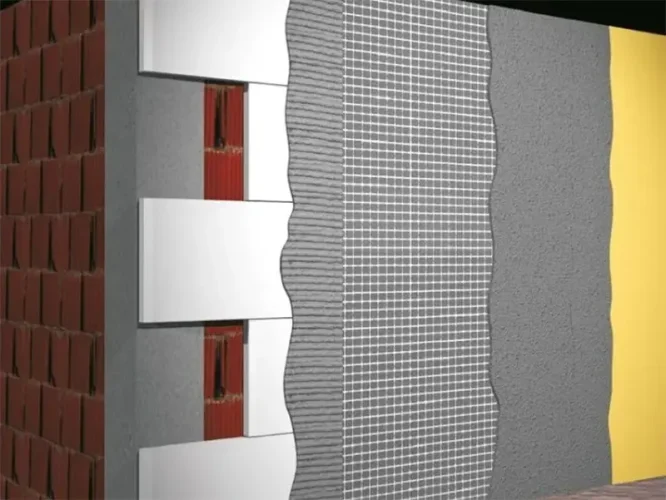

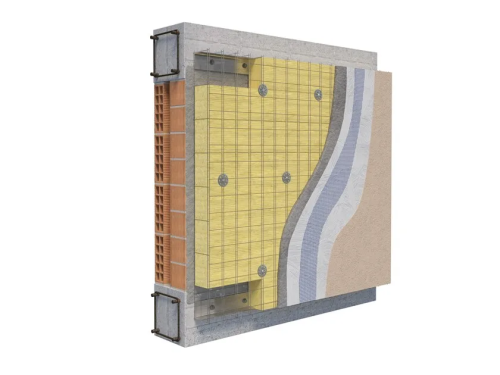

II. Key Components of an EIFS Wall System

- Adhesive:Bonds the insulation board securely to the substrate.

- Insulation Board:Typically Expanded Polystyrene (EPS) foam. This is the core EIFS insulation layer providing thermal resistance.

- Reinforced Base Coat:A critical layer embedding a reinforcing mesh (usually fiberglass). This coat provides impact resistance and a stable base for the finish. HPMC is a vital additive here, enhancing adhesion, workability, and water retention.

- Finish Coat:The visible, decorative, and protective outer layer, available in various textures and colors. HPMC also improves the application and durability of this coat.

III. EIFS vs. Stucco: Understanding the Difference

- Stucco:A traditional, cement-based plaster applied directly over a solid substrate (like masonry or wire lath). It’s relatively thin and offers minimal inherent insulation.

- EIFS:A layered system incorporating continuous insulation board. The base coat is typically polymer-modified cement or a synthetic blend, and the finish coat is much thinner than stucco. The EIFS exterior finish system prioritizes energy efficiency alongside aesthetics.

| Feature | EIFS (Exterior Insulation Finishing System) | Traditional Stucco |

| Material Composition | eifs construction material relies on polymer-modified mixes (requiring HPMC for adhesion, water retention, sag resistance). | Sand, Portland cement, lime, and water. |

| Water Management | Often includes drainage planes/moisture barriers. | Relies on mass and permeability; susceptible to water intrusion if cracked. |

| Primary Advantage | Superior energy efficiency + design versatility | Lower material cost; traditional aesthetic. |

| Application Complexity | Higher skill requirement. | Simpler application; established trade practices. |

| Typical Use Cases | Modern commercial/residential EIFS exterior; projects prioritizing energy efficiency (EIFS system). | Traditional architecture; regions with stucco heritage. |

IV. Major Benefits of HPMC for EIFS

Hydroxypropyl Methylcellulose (HPMC) is indispensable in high-quality EIFS construction material. Its key benefits include:

- Enhanced Workability & Sag Resistance:HPMC provides smooth application and prevents sagging on vertical surfaces, crucial for the base and finish coats in the EIFS wall system.

- Superior Water Retention:HPMC dramatically slows water loss from the wet mix, allowing cementitious materials to hydrate fully. This results in significantly stronger bonds within the etics system and reduces shrinkage cracking.

- Improved Adhesion:HPMC significantly boosts the adhesive strength of base coats to the eifs insulation board and the finish coat to the base coat, enhancing the overall integrity of the eifs exterior.

- Extended Open Time:Contractors gain more working time for applying and tooling base and finish coats, improving application quality in eifs siding

- Improved Crack Resistance:By promoting proper hydration and reducing shrinkage stresses, HPMC contributes to a more durable, crack-resistant eifs finish.

V. Where EIFS Excels: Common Applications

The versatility of the eifs system makes it a top choice for diverse projects, delivering energy efficiency, design freedom, and durable eifs exterior finishes.

Crucially, HPMC plays a vital role in ensuring the performance and longevity of the eifs construction material in these demanding settings:

1. Commercial Building Facades:

Modern office complexes, retail centers, and hotels leverage the EIFS exterior finish system for sleek aesthetics and superior insulation.

HPMC is essential here, ensuring the base coat adheres flawlessly to the EIFS insulation board and the finish coat applies smoothly over large areas, resisting sag and ensuring uniform texture critical for high-visibility projects.

2. Residential Construction (New Build & Renovation):

For both new homes and renovations, EIFS siding offers excellent thermal performance and curb appeal.

HPMC contributes directly to the durability homeowners expect, enhancing crack resistance in the base coat and finish, improving water retention for proper curing in varying weather, and boosting adhesion.

3. Institutional Projects (Schools, Hospitals, Government):

These buildings demand robust, long-lasting, and energy-efficient exteriors. The ethics systemexcels here.

HPMC ensures the base coat forms a strong, monolithic layer over insulation, enhancing impact resistance crucial for high-traffic areas.

4. Architectural Features & Complex Shapes:

One of the standout advantages of an eifs exterior finish systemis its ability to create intricate details, curves, and ornaments cost-effectively.

HPMC‘s workability enhancement is paramount here. It allows applicators to easily shape and tool both the reinforced base coat and the finish coat over complex substrates or around features, enabling the creation of unique eifs exterior finishes.

VI. Conclusion

HPMC is not just an additive; it’s a cornerstone of high-performance EIFS and etics systems. Its role in ensuring workability, adhesion, water retention, and ultimate durability is irreplaceable in both base and finish coats.