This article explains why HPMC is essential, how it works, and how choosing the right HPMC powder transforms your cement tile adhesive performance.

I. What is Hydroxypropyl Methylcellulose (HPMC)?

II. Why Add HPMC Powder to Tile Adhesives?

Adding HPMC powder to tile adhesives delivers vital performance benefits. Here’s why tile adhesive manufacturers rely on HPMC:

1. Stronger Water Retention:

HPMC can significantly reduce the loss of water to porous substrates and the air, ensuring that cement hydration and curing reach optimal conditions, thereby preventing the cement mortar from drying out prematurely and reducing the bonding strength.

2. Improved Workability & Open Time:

Hydroxypropyl methylcellulose lubricates the mixture, enhancing application and tooling. HPMC prolongs the time the adhesive remains workable and adjustable after application but before it sets.

3. Enhanced Adhesion Strength:

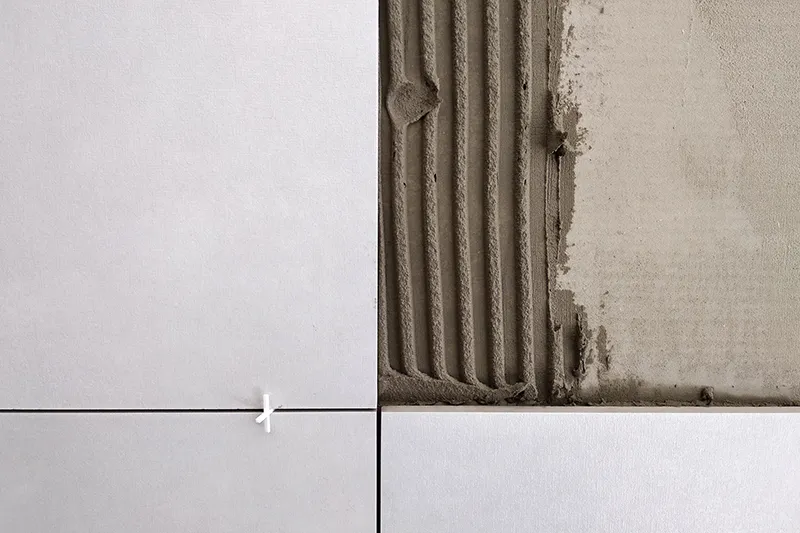

By forming a polymer film and improving water retention for full hydration, HPMC boosts the ultimate bond strength between the tile, adhesive, and substrate.

4. Excellent Anti-Sag Performance:

HPMC acts as a thickening binder, providing high viscosity and structural stability to tile adhesives. This prevents tiles from sliding or sagging on vertical surfaces during installation.

III. Choosing the Correct HPMC Grade for Tile Adhesives

Not all HPMC powders are the same. Selecting the right grade is crucial for optimal cement tile adhesive performance. Key factors include:

1. Viscosity (Measured in mPa.s):

Viscosity is a critical property of Hydroxypropyl Methylcellulose (HPMC) for tile adhesives. HPMC primarily thickens the adhesive by increasing the viscosity of its aqueous phase.

Standard testing defines HPMC viscosity: A 2% aqueous solution is measured at 20°C using a specified rotational viscometer at 20 rpm. This measured value serves as a key performance indicator.

- Low Viscosity (e.g., 40,000 – 60,000 mPa.s):Offers good workability and sag resistance with faster wetting/mixing. Suitable for standard thin-bed adhesives.

- Medium Viscosity (e.g., 75,000 – 100,000 mPa.s):Provides excellent balance of water retention, anti-sag, and open time. The most common choice for versatile cement tile adhesive formulations.

- High Viscosity (e.g., 150,000 – 200,000 mPa.s+):Delivers maximum water retention, extended open time, and superior anti-sag for thick-bed applications, large tiles, or challenging conditions. May slightly reduce workability.

2. Surface Treatment:

Surface Treatment is a specialized process applied to Hydroxypropyl Methylcellulose (HPMC) powder particles. It involves modifying the outer surface of the particles with a very small amount (typically <1%) of a cross-linking agent (often glyoxal). This creates a temporary, water-insoluble film on the particle surface.

| Feature | Surface-Treated HPMC | Non-Surface-Treated HPMC |

|---|---|---|

| Surface Chemistry | Outer surface temporarily cross-linked (hydrophobic barrier) | Untreated, fully hydrophilic surface |

| Initial Water Contact | Hydrophobic surface repels water initially | Hydrophilic surface attracts water immediately |

| Dispersion in Water | Powders disperse freely without lumping | Prone to rapid surface gelation and lumping |

| Dissolution Speed | Dissolves after dispersion is complete | Starts dissolving and thickening on contact |

| Key Advantages | Superior dispersibility, lump-free mixing, simplified processing, cold water soluble | Simpler manufacturing, potentially slightly faster ultimate dissolution, lower cost (sometimes) |

3. Application Grade:

- Construction Grade HPMC:Specifically purified and tested for use in building materials like cement tile adhesive. It meets stringent performance and consistency standards for this demanding application. Contains controlled levels of salts and impurities to avoid negative effects on setting or strength.

- Other Grades (Food Grade HPMC, Pharma Grade HPMC, Cosmetic Grade HPMC): These HPMC undergo different purification processes targeting specific regulatory standards like low endotoxin levels.

IV. HPMC Selection for Different Tile Adhesive Scenarios

1. Standard Cement-Based Tile Adhesive

For bonding ceramic or porcelain tiles on walls and floors under typical conditions, Hpmc for tile adhesiveis essential.

Medium viscosity hpmc grades provide the perfect balance, delivering excellent water retention to ensure full cement hydration and strong adhesion in your cement tile adhesive.

This tile adhesives hpmc powder also offers good workability and sufficient open time for tile adjustment, making it a reliable choice from quality Hpmc manufacturers.

2. Adhesive for Large Format Tiles

Installing heavy, large tiles requires hpmc for tile adhesivethat prevents sagging and slippage.

High viscosity hpmc grades deliver superior anti-sag properties, securely holding these tiles in place on vertical surfaces.

While providing critical water retention, this cement tile adhesive hpmc solution ensures tiles stay positioned correctly during setting.

3. Fast-Setting Tile Adhesive

When projects demand rapid strength development for early grouting or foot traffic, the right hpmc for tile adhesiveaccelerates the process.

Lower viscosity hpmc grades are typically chosen; they maintain necessary water retention but allow faster water release, contributing to quicker setting and strength gain without overly sacrificing workability in the tile adhesive.

4. Flexible Tile Adhesive

For surfaces prone to movement, like wooden substrates or underfloor heating, or areas needing crack-bridging, hpmc for tile adhesive plays a vital support role. Medium viscosity hpmc ensures excellent water retention and workability in the cement tile adhesive.

V. Conclusion

Hydroxypropyl Methylcellulose is not just an additive; it’s the backbone of high-performing modern tile adhesives. Its unparalleled ability to retain water, improve workability, prevent sag, extend open time, and boost adhesion makes HPMC indispensable for formulators.

Partner with a reliable China HPMC manufacturer committed to quality and expertise. Tenessy Hydroxypropyl Methylcellulose delivers consistent performance your tile adhesive formulations demand. Contact us today to discuss your specific requirements and discover how our HPMC can elevate your product.