As HPMC manufacturers and suppliers, we are often asked, “Does the viscosity of HPMC affect its price?” The answer to this question is actually more complex than a simple yes or no. Let us explain the key factors involved and how you, our valued customer, should select the most cost-effective grade of HPMC for your application.

I. Understanding HPMC Viscosity

1. How viscosity affects application performance

The viscosity of HPMC has a direct impact on its performance in a variety of industries:

- Construction Industry: High viscosity HPMC can effectively enhance water retention and improve adhesion in applications such as dry-mix mortar and tile adhesive, thus ensuring better adhesion of the material to the substrate.

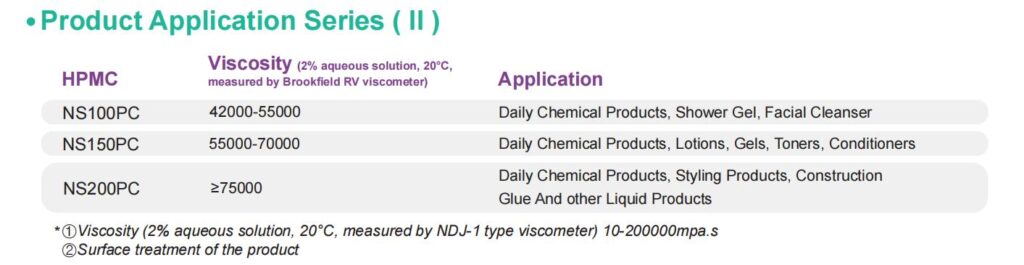

- Daily Chemicals: In products such as shampoos and body washes, medium-viscosity HPMCs are often used to adjust fluidity and ensure smoothness and uniformity when the product is used.

- Coatings Industry: Low viscosity HPMC is used in coatings and paints to improve flow and spreadability, making the coating uniform and easy to apply.

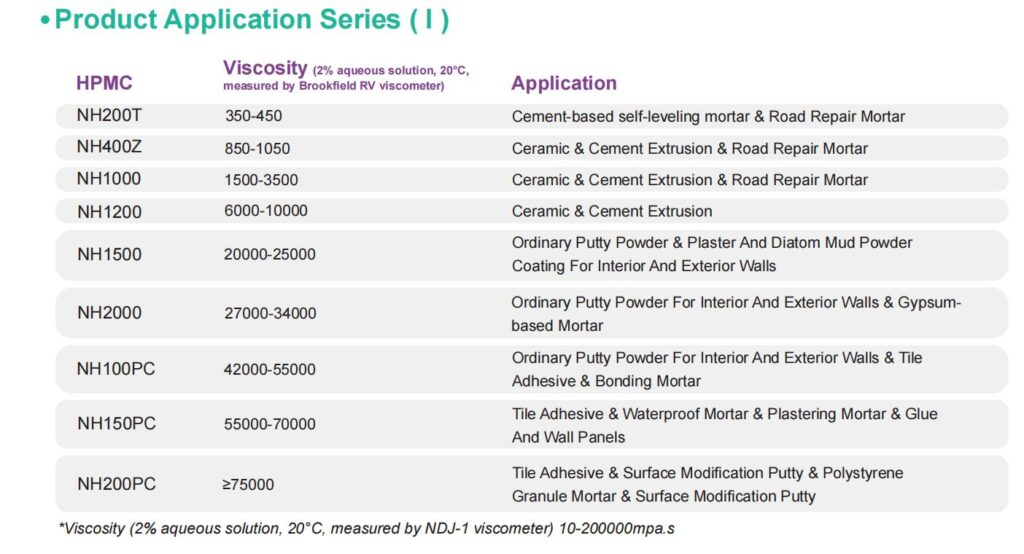

2. Common application grades of HPMC

- Low Viscosity (100-2000 mPa.s): For applications requiring high flowability, such as self-leveling mortars and liquid detergents.

- Medium Viscosity (2000-50,000 mPa.s): Widely used in tile adhesives, putty powders and coatings in the construction industry, with a good balance of performance and price.

- High Viscosity (50,000+ mPa.s): Typically used in construction materials requiring high water retention and enhanced bonding, such as wall repair mortars.

II. How Viscosity Affects the Cost of HPMC

1. Higher viscosity HPMC: is it always more expensive?

Typically, higher viscosity HPMC is more expensive because it requires a more sophisticated production process and higher quality raw materials. However, it is not always the case that every high-viscosity product is more expensive. Due to market demand, production process optimization, and supply chain factors, some high-viscosity HPMCs may not be more expensive than low-viscosity products. Therefore, the price is not entirely determined by viscosity, but also closely related to other factors.

2. Cost differences between low, medium and high viscosity grades

- Low Viscosity HPMC: Relatively simple to produce, low cost, suitable for large-scale applications.

- Medium Viscosity HPMC: A balance between performance and cost, widely used in most industries.

- High Viscosity HPMC: Although production costs are higher, the use of high-viscosity HPMC is more cost-effective in terms of improving material performance.

3. Special applications and their impact on HPMC prices

For some special applications, such as pharmaceutical grade HPMC, its production requires stricter quality control and higher purity, so the price is usually higher. In addition, customized viscosity products or HPMC for specific industry requirements may also lead to higher prices due to their special production requirements.

III.The Key Factors Affecting the Price of HPMC

1. The impact of raw material costs on HPMC prices

The main raw material of HPMC is cellulose, usually from wood pulp or cotton. The price fluctuations of raw materials directly affect the production cost of HPMC. For example, a tight supply of cellulose or an increase in raw material prices usually leads to an increase in the cost of HPMC. Therefore, the quality and stability of purchased raw materials are also key factors in ensuring cost control.

2. Impact of production process on HPMC price

The production process of HPMC is relatively complex, involving multiple steps such as chemical modification, dissolution and moisture control. Higher viscosity HPMC requires finer production control and longer processing time, which leads to its higher cost. The equipment used in the production process, the energy required and the level of technology also affect the final price.

3. Market demand for different viscosity grades

Market demand for different viscosity grades of HPMC affects its price. For example, the construction industry has a higher demand for high viscosity HPMC, which drives up the price. In contrast, the demand for medium viscosity products in the daily-use chemicals industry is stable, with less price fluctuation. Changes in market trends and demand are an important factor in price fluctuations.

IV.HPMC Price for Different Industry Applications

1.Construction

In the construction industry, HPMC is widely used in tile adhesive, dry mix mortar, putty powder and other construction materials. The performance of high viscosity HPMC is especially important because it can significantly improve the bonding force and water retention of the material, thus extending the durability of the material after construction. Although high-viscosity HPMC is more expensive, the benefits of its improved performance can completely make up for the cost difference in terms of long-term use.

2.Pharmaceuticals

Pharmaceutical grade HPMC is used in the pharmaceutical industry for coating, capsules and controlled release formulations. Since these applications require highly pure raw materials and precise viscosity control, pharmaceutical grade HPMC is usually more expensive than common industrial grade products. Choosing the right viscosity and purity is critical to ensure drug efficacy and patient safety.

3. Latex paints and coatings

In the coatings and paints industry, HPMC is mainly used to improve the fluidity and dispersion of coatings. HPMCs of different viscosities are used in different paint formulations to optimize coating results. While lower viscosity HPMCs are less expensive, higher viscosity HPMCs offer higher performance in terms of enhancing adhesion and flow of coatings. The right balance of price and performance is key when selecting HPMC for coatings.

V. Tips for Choosing the Right HPMC Grade within Your Budget

1. Understand your application requirements

When choosing HPMC, first of all, you need to clarify your application requirements. For example, is there a need for enhanced bonding, water retention, or improved flow? HPMCs with different viscosities perform differently in different areas, so understanding your needs is the first step in choosing the right product.

2. How to evaluate the price/performance ratio

When evaluating the price to performance ratio of HPMC, you need to consider the actual effect and long-term value of the product. Choosing the right grade of HPMC not only ensures application effectiveness, but also achieves optimal performance within a reasonable budget. The balance between price and performance will directly affect your ROI.

3. Partner with a reliable hpmc supplier for cost effectiveness

VI. Summary

Therefore, viscosity is not the only factor that determines HPMC, but other factors such as raw materials, production processes and market demand also influence the price.