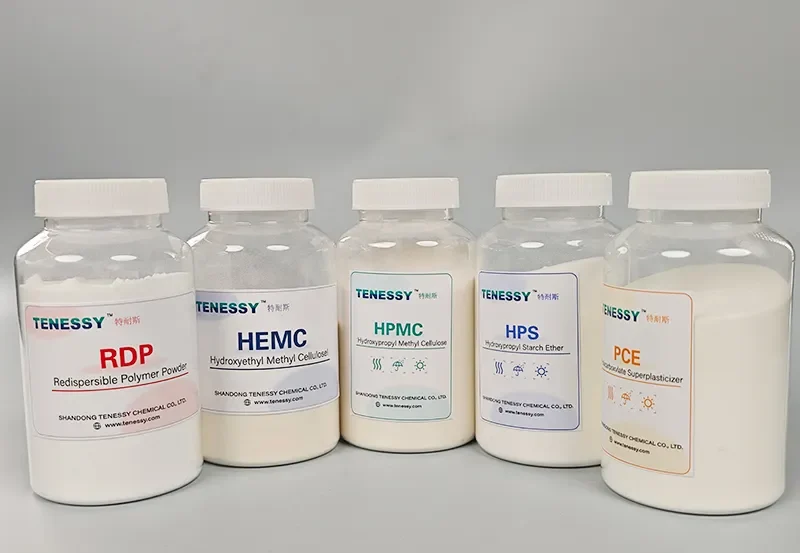

In this guide, we’ll look at five basic additives for mortar – HPMC and HEMC (cellulose ether), RDP (Redispersible Polymer Powder), PCE (Polycarboxylate Superplasticizer),SHP (Silicone hydrophobic Powder), and HPS (Hydroxypropyl Starch Ether)-what they do, where they are applied. And how they can be effectively combined for optimum performance.

I.Understanding Additives for Mortar: Why They are Essential

The role of additives in mortar performance is critical. Without the correct additives, mortar may suffer from poor workability, shrinkage cracks, water absorption and weak bonding. Key benefits of mortar additives include:

- Improved adhesion to various substrates.

- Enhanced water retention and reduced premature drying.

- Increased flexibility and crack resistance.

- Better workability and easier application.

- Higher durability and water resistance.

II.The 5 Essential Additives for Mortar and Their Functions

1.HPMC & HEMC - The Backbone of Mortar Workability

HPMC and HEMC are water-soluble cellulose ethers that improve mortar properties by enhancing water retention, consistency, and adhesion.

Key Benefits:

- Water Retention: Reduces premature drying, ensuring proper cement hydration.

- Improved Workability: Enhances mortar consistency and ease of application.

- Sag Resistance: Prevents slippage in vertical applications such as tile adhesives.

- Extended Open Time: Provides workers more time for adjustments.

Applications:

2.RDP - Enhancing Adhesion & Flexibility

Redispersible Polymer Powder (RDP) is a polymer additive that improves bonding strength, flexibility, and crack resistance. It is derived from polymer emulsions and can be redispersed in water, forming a strong polymer film within the mortar.

Key Benefits:

- Enhanced Bond Strength: Provides strong adhesion to various substrates.

- Flexibility & Crack Resistance: Reduces shrinkage cracks.

- Improved Water Resistance: Helps prevent moisture-related issues.

Applications:

- Tile adhesives

- Repair mortars

- Self-leveling mortars

- Exterior wall insulation systems

3.PCE - Optimizing Flowability

Polycarboxylate Superplasticizer (PCE) is an advanced high-performance water-reducing agent that enhances mortar fluidity while maintaining strength.

Key Benefits:

- Water Reduction: Improves density and strength without compromisingworkability.

- Increased Flowability: Ideal for self-leveling applications.

- Enhanced Pumping Performance: Reduces viscosity and improves ease of application.

Applications:

- Self-leveling mortar

- High-performance concrete

- Repair mortars

4.SHP - Waterproofing & Moisture Resistance

Silicone Hydrophobic Powder (SHP) is an additive designed to make mortar hydrophobic, reducing water absorption and increasing durability in wet conditions.

Key Benefits:

- Waterproofing: Prevents water infiltration and efflorescence.

- Improved Durability: Reduces freeze-thaw damage.

- Breathability: Maintains vapor permeability while repelling water.

Applications:

- Cement-based renders

- Exterior coatings

- Waterproof mortars

5. HPS - Enhancing Thickening & Workability

Hydroxypropyl Starch Ether (HPS) is a modified starch that enhances thickening, anti-sagging properties, and overall workability.

Key Benefits:

- Improved Consistency: Ensures uniform application.

- Anti-Sagging Properties: Prevents vertical slip in thick-layer applications.

- Smooth Application: Works synergistically with cellulose ethers for better thickening.

Applications:

- Tile adhesives

- Gypsum-based mortars

- Decorative plasters

III. How to Optimize Mortar Performance with Proper Additive Combinations

1.Selecting the correct additive combination ensures maximum efficiency and performance.

Some key recommendations:

- For Tile Adhesives: HPMC/HEMC + RDP + HPS for adhesion, flexibility, and workability.

- For Self-Leveling Mortar: PCE + RDP for enhanced flowability and strength.

- For Waterproof Mortars: SHP + RDP for improved water resistance.

- For Repair Mortars: HPMC + RDP + PCE for adhesion and durability.

2.Example of tile adhesive formula

| Combination | Dosage (%) | Function |

| Cellulose Ether + RDP | 0.2% – 0.5% + 1% – 2% | Improves water retention and bond strength |

| SHP | 0.1% – 0.3% | Enhances waterproof performance, suitable for bathrooms and kitchens |

3.High-performance self-leveling mortar

| Combination | Dosage (%) | Function |

| PCE + Cellulose Ether | 0.2% – 0.5% + 0.05% – 0.1% | Achieves high fluidity and low shrinkage |

| RDP | 1% – 2% | Improves surface abrasion resistance |

4.Factors affecting the effect of additives for mortar

4.1 Climatic conditions

Humidity and temperature affect the performance of additives.

Dry areas: give priority to high water retention cellulose ether.

Rainy environment: with SHP to enhance waterproof.

4.2 Construction process

Different construction methods to choose different additives.

Mechanical spraying: choose low viscosity mortar containing PCE.

Manual plastering: add RDP to improve maneuverability.

4.3 Substrate type

Different materials require different bonding properties.

4.4 Mix design

Appropriate dosage ensures optimum performance.

IV. Other Key Considerations for Using Additives for Mortar

- Sustainability: Eco-friendly additives can reduce environmental impact.

- Storage & Handling: Proper storage prevents degradation of additives.

- Compatibility Testing: Essential to avoid negative interactions between additives.

V. Conclusion & Final Recommendations

Additives for mortar play a critical role in improving strength, adhesion, water resistance and workability. Understanding the function of each additive – HPMC and HEMC, RDP, PCE, SHP and HPS – allows construction professionals to optimize formulations for specific applications.

By choosing the right additives for mortar, construction projects can achieve greater durability, better performance and long-lasting results. Be sure to try different formulations and conduct compatibility tests to maximize the effectiveness of your mortar mix.

Would you like to learn more about how to customize these additives for your specific project? Please feel free to contact us!