I.What is Hydroxypropyl Methyl Cellulose Raw Material?

1.Overview of hpmc raw materials

Hydroxypropylmethylcellulose (HPMC) is a versatile polymer with excellent water retention, thickening and film-forming properties.The quality of HPMC is related to its raw materials. For HPMC to perform well, whether in construction, pharmaceutical or personal care products, the ingredients used to make it must meet high standards.

The main raw material for HPMC is cellulose, a natural polymer found in plants. However, the quality, purity and source of this cellulose can significantly affect the performance and consistency of the final HPMC product. Manufacturers must carefully select raw materials to meet the diverse needs of industries ranging from construction to pharmaceuticals.

2.Key criteria for selecting raw materials in hpmc production

HPMC products offer consistent viscosity, excellent water retention and ease of use. To achieve these properties, the raw materials used in HPMC production must meet several key criteria:

- High Purity: Impurities can negatively impact performance, especially in delicate applications such as pharmaceuticals.

- Reliable Supply Chain: Raw materials must come from reliable suppliers to avoid production disruptions.

- Environmental Compliance: As sustainability becomes increasingly important, manufacturers are choosing materials that minimize environmental impact.

II.Primary Raw Materials for Hydroxypropyl Methyl Cellulose

1.Refined cotton: the core ingredient

2.Alternative raw materials in hpmc

While refined cotton is the preferred choice, other raw materials can also be used for HPMC production, for example:

- Wood Pulp

Wood pulp is a more economical choice in HPMC, but it contains more impurities, which can affect the stability of the resulting HPMC product.

- Regenerated Cellulose

Other regenerated cellulosics are environmentally friendly, but their quality is unstable and limited in high performance applications for HPMC.

3.Why refined cotton is preferred for premium hpmc products

Refined cotton is the best choice for HPMC products because of the following characteristics:

- Superior Purity: minimal impurities ensure consistent viscosity and performance in a variety of formulations.

- Consistent Quality: refined cotton undergoes rigorous processing to meet the high standards required for premium HPMC.

- Improved Process Efficiency: the compatibility of refined cotton with chemical reagents reduces waste and increases throughput during production.

III.Why TENESSY Chooses Superior Refined Cotton for Hydroxypropyl Methyl Cellulose

1.The advantages of high-purity refined cotton

- Consistent Quality: High-purity refined cotton ensures that every batch of HPMC delivers the same reliable performance, reducing variation for customers.

- Reduced Impurities, Improved Performance: With fewer impurities, the resulting HPMC has excellent viscosity, water retention and stability, making it suitable for demanding applications.

2.TENESSY’s raw material procurement standards

TENESSY follows strict industry regulations to source the highest quality refined cotton. We work with reliable suppliers with consistent quality to ensure the uniform quality of our products.

3.How high-quality refined cotton impacts hpmc applications

Through the use of high quality refined cotton, TENESSY ensures that its HPMC products excel in the following applications:

- Construction: processability and longer open time in tile adhesives.

- Pharmaceuticals: Safe, consistent formulations for controlled drug release.

- Personal Care: Smooth textures and stable emulsions in creams and lotions.

IV.The Role of Other Raw Materials in Hydroxypropyl Methyl Cellulose Production

1.Alkalis and their function in the production process

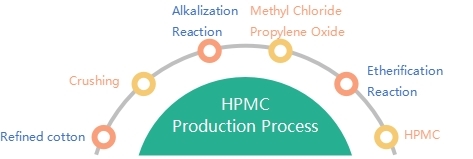

Alkalis (usually sodium hydroxide, also known as caustic soda) are an important ingredient in the HPMC production process. Alkalis help break down fibers and make cellulose easier to combine with other chemicals. In the presence of alkali, cellulose molecules are more active and efficiently react with propylene oxide and chloromethane.

2.Propylene oxide and methyl chloride as key reagents

- Propylene Oxide: Introduces the Hydroxypropyl group to HPMC. This group gives HPMC excellent water solubility and allows it to dissolve quickly in cold water, making it particularly suitable for use in high efficiency construction adhesives.

- Methyl Chloride: It is used to introduce Methyl group to enhance the stability and anticorrosive property of HPMC, so that it still maintains good performance under adverse conditions.

3.TENESSY related customer cases

A customer, a coating manufacturer, found that the HPMC they used was prone to slow dissolution or caking problems at low temperatures, which directly affected the market reputation of the coating.

Problem: The purity of propylene oxide in the HPMC supplied by the supplier was slightly low, resulting in poor dissolution performance of the product.

Solution: After TENESSY provided HPMC produced with high purity propylene oxide, the product dissolved better in cold water, the dissolution time was significantly shortened, and the dissolution uniformity was improved, which solved the customer’s problem.

V.How TENESSY Ensures Top-Quality Hydroxypropyl Methyl Cellulose Raw Materials

In addition to the core cellulose and auxiliary reagents, TENESSY produces HPMC with strict quality control of other materials. This includes:

- Purity Testing: Ensuring that there are no excessive impurities in the alkalis, propylene oxide and chloromethane that could interfere with the reaction process or increase the risk of residues.

- Supply Chain Management: The procurement of high-quality raw materials is of vital importance. TENESSY selects reliable suppliers to ensure material traceability. Comply with international quality and environmental standards.

- Environmental Safety Checks: when using these chemicals, TENESSY takes environmental protection measures to control emissions and ensure that the environmental impact of the production process is minimized.

VI. Conclusion and TENESSY

Hydroxypropyl Methyl Cellulose (HPMC) cannot be produced without high quality raw materials, including refined cotton, alkaline substances, propylene oxide and chloromethane. The purity and performance of each raw material will directly affect the final quality and application effect of HPMC.

TENESSY always insists on using high-quality refined cotton as the core raw material, and at the same time, strictly controls the quality of auxiliary raw materials to ensure that each batch of HPMC meets the high standard of customers’ needs.

TENESSY has demonstrated its expertise and reliability in the construction, pharmaceutical and household chemical industries by supporting customers in real-life cases. Whether it is optimizing the performance of ceramic tile adhesives, improving tablet production processes or developing environmentally friendly mortars and industrial cleaners, TENESSY offers tailor-made solutions.

Choosing TENESSY means choosing a trusted HPMC supplier that will support your products with higher quality and consistency.