This article explores what MHEC is, how it functions, and where it is used—focusing on its benefits in cement-based products, wall putty, and water-based paints. Whether you’re looking for a MHEC manufacturer, comparing cellulose ether HEMC options, or sourcing a customized MHEC methylcellulose grade for your application, this guide is for you.

I.What is Methyl Hydroxyethyl Cellulose (MHEC)?

MHEC is a type of cellulose ether derived from natural wood pulp and chemically modified through methylation and hydroxyethylation. This results in a versatile polymer that dissolves easily in cold water and delivers excellent rheological control in dry mix mortars and coatings.

Compared to other cellulose ethers:

II.Applications of MHEC in Construction Materials

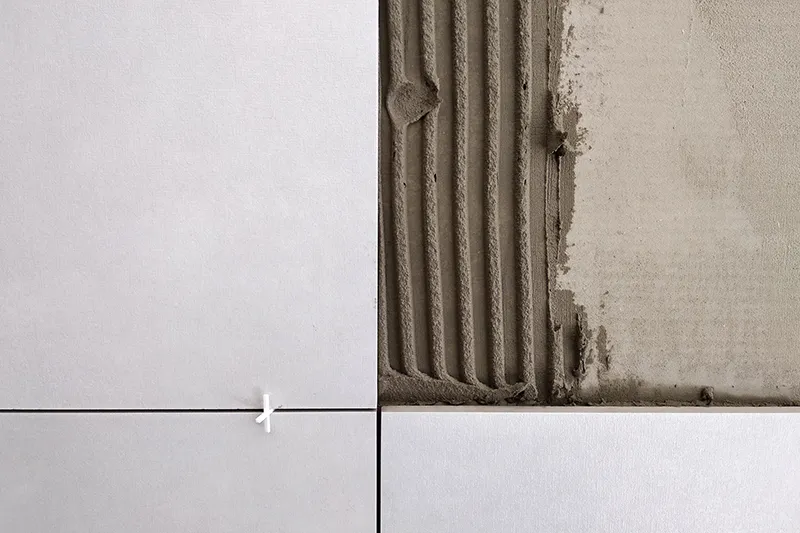

1.Tile Adhesives

MHEC ensures better adhesion between the tile and substrate by retaining moisture during the curing process.

Boost anti-sagging capabilities, particularly for tiles on vertical walls.

Improve workability to allow installers to work more smoothly and for longer periods of time.

Contractors and tile adhesive manufacturers work with HEMC suppliers. TENESSY can provide customized MHEC methylcellulose blends that meet local tile laying standards.

2.Wall Putty and Skim Coats

Smooth application and trowelability.

Superior water retention that ensures proper hydration of cement.

Resistance to cracking and powdering after drying.

By improving workability and reducing shrinkage, MHEC allows for thinner and more uniform coats with excellent bonding strength.

3.Ready-Mixed Mortars and Plasters

In ready-mixed mortar systems—used for bricklaying, rendering, and patching—MHEC contributes to:

Consistent thickening and suspension of solids.

Extended open time and better finish.

Reduced segregation and bleeding.

The use of high-quality cellulose ether HEMC improves both the wet and dry performance of mortar.

4.External Wall Insulation Systems (EIFS)

Excellent bonding between insulation boards and exterior layers.

Good slip resistance and sag control during vertical application.

Crack resistance after curing due to better water retention.

HEMC suppliers optimize MHEC dosage and viscosity grade of MHEC based on the actual needs of customers to ensure its compatibility with cement, sand and other system components.

III.Role of MHEC in Water-Based Paints and Coatings

1.Interior and Exterior Emulsion Paints

In architectural coatings, MHEC is valued for its:

Thickening ability, delivering consistent viscosity and brush feel.

Film formation support, ensuring even drying and coverage.

Suspension properties, preventing pigment settling and extending shelf life.

Compared to other cellulose ether products, MHEC material offers enhanced storage stability and is less sensitive to pH changes in waterborne systems.

2.Texture and Decorative Coatings

MHEC also plays a key role in high viscosity decorative coatings.

Provides strong pseudoplasticity for improved workability.

Enhances consistency of thick textured patterns.

Enhances adhesion to a variety of surfaces including concrete, stucco and drywall.

Painters benefit from better leveling and reduced spatter, while manufacturers benefit from more stable, durable coating formulations.

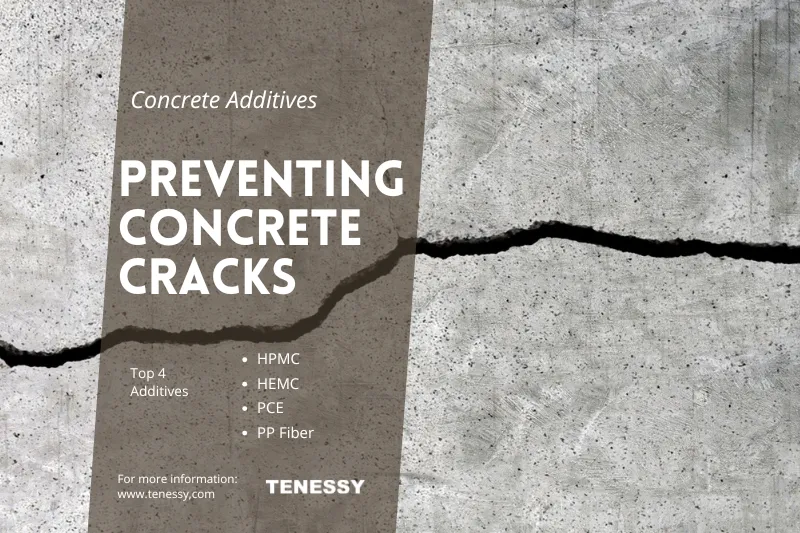

IV.Advantages of Using MHEC in Building and Coating Formulations

Here are the main benefits that make MHEC stand out:

High water retention, reducing cracking and enhancing curing.

Improved workability, enabling smoother application and less fatigue for workers.

Versatility, compatible with a wide range of dry-mix mortar and water-based paint formulations.

Enzyme resistance, enhancing shelf life in tropical and humid conditions.

Customizability, with many MHEC manufacturers offering customized MHEC methylcellulose for specific climate or material needs.

V.How to Select the Right MHEC for Your Application

Choosing the proper grade of MHEC depends on:

Viscosity: High viscosity for tile adhesive, medium to low for skim coats and paints.

Particle size: Finer particles dissolve faster, preferred in dry mixes.

Substitution level: Affects solubility, gel strength, and compatibility.

Consult with TENESSY’s technical support team as a HEMC supplier or MHEC manufacturer to test and recommend the best product for your specific formulation.

VI.Conclusion

Methyl hydroxyethyl cellulose (MHEC) is more than just a thickener—it’s a vital ingredient in improving the performance and reliability of both construction mortars and decorative coatings. As a high-performing cellulose ether HEMC, it offers exceptional workability, durability, and finish quality across a range of products.

Whether you’re formulating tile adhesives, skim coats, or premium paints, sourcing the right HEMC material from trusted MHEC manufacturers can give you a strong competitive edge.