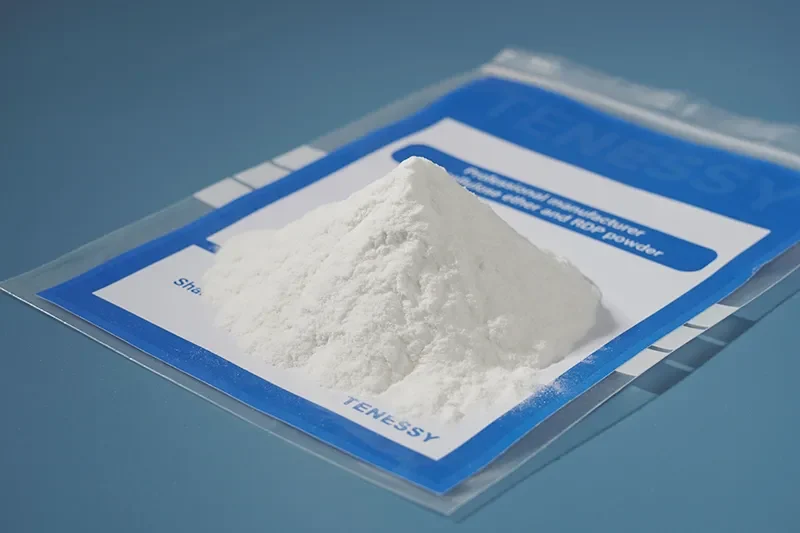

As a leading HPMC powder manufacturer, TENESSY specializes in providing high quality HPMC binder for various industries. We have advanced manufacturing technology and strict quality control. This ensures that our HPMC products have excellent adhesion, water retention and stability in different applications.

Since HPMC (Hydroxypropyl Methyl Cellulose) have thickening, film-forming and adhesive properties. They are therefore widely used in the construction, pharmaceutical, coatings and food industries. Choosing a reliable HPMC binder supplier is essential for ensuring product consistency and performance.

TENESSY stands out as a trusted partner by delivering:

- Premium HPMC binder with consistent quality

- Customizable solutions to meet specific industrial needs

- Expert technical support for formulation and application

I.How TENESSY Manufactures High-Quality HPMC Binder

1. Raw Material Selection

TENESSY sources high-purity refined cotton cellulose, ensuring low ash content and excellent chemical stability.

2. Etherification Process

- HPMC is produced through a controlled etherification reactioninvolving methyl chloride and propylene oxide.

- The reaction parameters are carefully optimized to achieve desired viscosity, substitution degree (DS), and gel temperature.

3. Drying and Grinding

- The synthesized HPMC is dried and finely milledto achieve uniform particle size distribution.

- This enhances its solubility and dispersionin different applications.

4. Strict Quality Control

- Viscosity, moisture content, and purity are tested in each batch.

- TENESSY follows ISO standards, ensuring consistency in every production lot.

By maintaining rigorous quality control, we guarantee that our HPMC binder meets industry-specific requirements, making it a reliable choice for global customers.

II.How to Formulate HPMC Binder for Different Applications

The proper formulation of HPMC ensures optimal performance in various industries. Here’s how to use HPMC effectively:

1. General Guidelines for HPMC Binder Preparation

- Dissolution method: Slowly add HPMC powder into water while stirring to prevent clumping.

- Water temperature: Use cold water for dispersion, then heat to fully dissolve (for non-instant types).

- Concentration control: Adjust the HPMC content based on the required viscosity and adhesion.

2. Key Factors Affecting HPMC Binder Performance

- Viscosity: Higher viscosity HPMC provides better binding but requires more stirring for dissolution.

- Degree of substitution (DS): Affects solubility and film-forming properties.

- Particle size: Finer powders dissolve more easily.

3. Application-Specific Formulations

Construction Industry (Tile Adhesives & Mortars)

- Use medium to high viscosity HPMC binder for improved adhesion and workability.

- Recommended dosage: 2%–0.5% of total dry mix weight.

- Enhances water retention, preventing premature drying of mortar.

Pharmaceutical Industry (Tablet Binding & Coating)

- Use low-viscosity HPMC binderfor tablet binding and controlled drug release.

- HPMC ensures film integrity and stability in coating applications.

Paints & Coatings Industry

- Use low to medium viscosity HPMCfor thickening, anti-sagging, and dispersion stability.

- Controls rheology, preventing pigment sedimentation.

III.Key Applications of HPMC Binder Across Industries

1. Construction Industry

- Improving adhesion strength

- Enhancing water retentionfor extended workability

- Providing anti-sagging propertiesfor easier application

2. Pharmaceutical Industry

- Excellent binding propertiesfor tablet compression

- Controlled releasefor sustained drug delivery

- Improved solubility and bioavailability

3. Paints & Coatings Industry

- Increased viscosity for better coverage

- Enhanced dispersion of pigments

- Film-forming properties for durability

IV.TENESSY’s Commitment to Quality and Consistency in HPMC

At TENESSY, we prioritize:

1. Strict Batch-to-Batch Consistency

- Advanced automated productionensures uniform quality in every batch.

- Each batch undergoes rheological, thermal, and mechanical testing.

2. Advanced R&D and customization

- TENESSY’s R&D team develops tailored HPMC solutions.

- Custom formulations based on viscosity, substitution degree, and solubility requirements.

V. Why Choose TENESSY as Your HPMC Binder Supplier?

1. High-Quality HPMC Binder at Competitive Prices

- Large-scale production capacityensures cost-effective solutions.

- Direct factory supply eliminates middlemen, offering better pricing and stable availability.

2. Technical Support & Customization

- Our expert team provides formulation guidancefor specific applications.

- Customized HPMC solutionsavailable for unique industry requirements.

3. Reliable Global Supply Chain

- Efficient logisticsensure timely delivery worldwide.

- Large inventory stock minimizes supply disruptions.

VI. Conclusion: Partner with TENESSY for High-Performance HPMC Binder

Choosing TENESSY means:

Contact us today to discuss how TENESSY can enhance your product performance with our premium HPMC.